Pacmac manufactures tube filling and cartoning machines for the CPG industry. The company is spread out to three units, manufacturing packaging machines, with state-of-the-equipment.

Pacmac’s mission is to develop technologically adept machines, designed and manufactured in India, with a focus on robustness and customer satisfaction.

Automate cartoning process for easy product changeovers

Provide flexible machine design for global markets

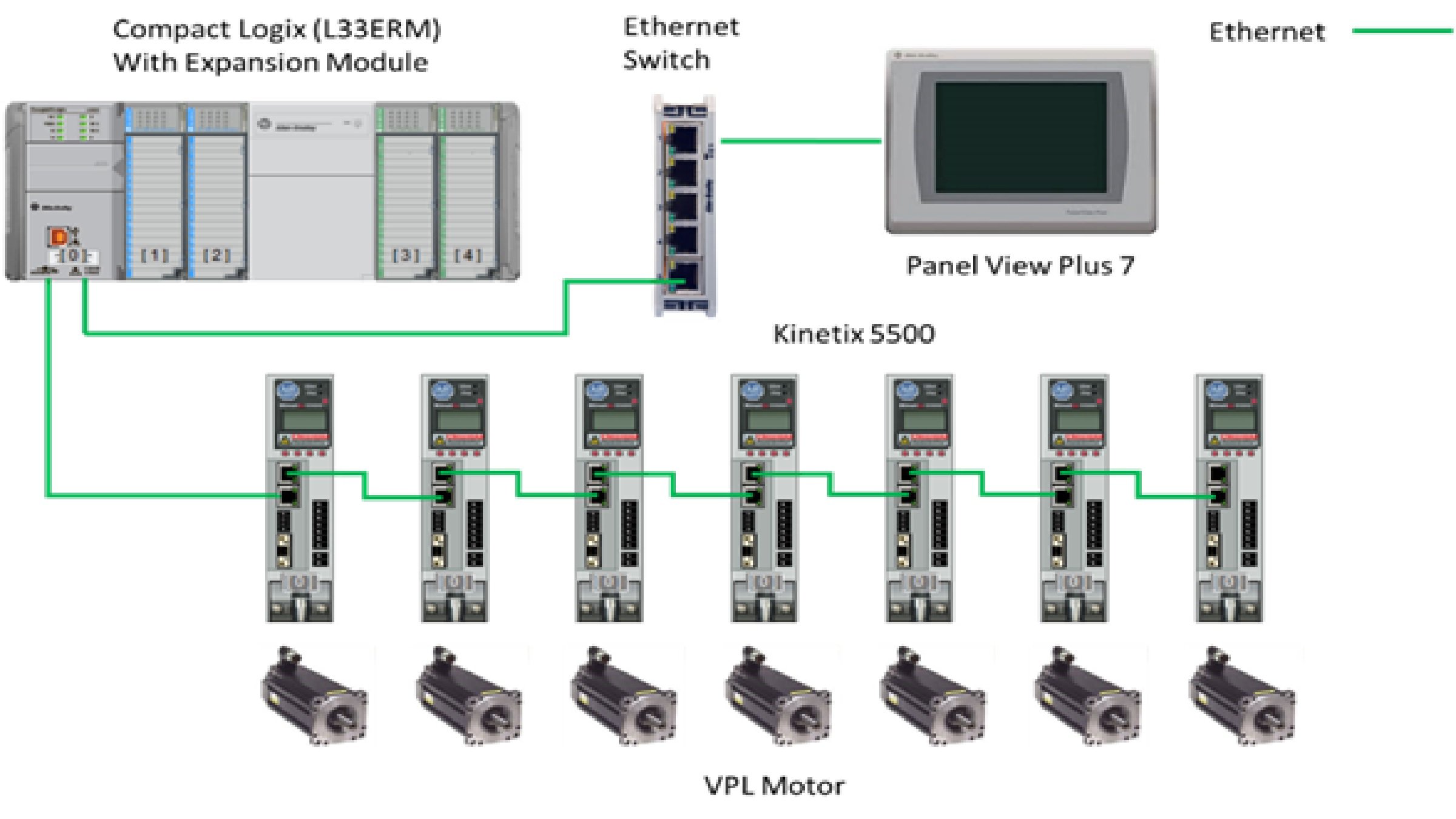

CompactLogix™

Kinetix® 5500 EtherNet/IP Servo Drives

Kinetix® VP-Series Servo Motors

Faster product changes

More accurate cartooning

Challenge

Pacmac was in need of an automated cartoning machine that could quickly and easily accommodate varied packaging sizes.

The typical challenge faced by Pacmac with the old machine was the open loop. There was no data exchange, and involvement of many mechanical components decreased accuracy over a period. When the size of the carton changes, the axis of the machines required manual adjustments to compensate the offset. The absolute position of the main motor could not be determined in case of power failure causing product loss, and failure of the main motor leads to a complete stoppage of machine.

Additionally, the old machines were limited in the ability to handle tube variations. With enhanced architecture, the same machine could carton products in multiple variations without machine stoppage by simply selecting a different tube type from the HMI.

Solution

Developing a new machine to handle varied carton types, increase productivity, and efficiency.

Pacmac partnered with Rockwell Automation to develop a new cartoning machine with an automated product changeover feature to meet increased global demand.

Rockwell designed a solution for Pacmac, which is powered by CompactLogix™, Kinetix® 5500 EtherNet/IP Servo Drives, and Kinetix® VP-Series Servo Motors. The new machine has the axis connected to the servo motor, which is on Kinetix® 5500 EtherNet/IP™ for communication with the controller, eliminating the manual mechanical system.

CompactLogix controllers provide higher performance, increased capacity, improved productivity, and enhanced security to help meet the growing demands of smart machines and equipment for manufacturing.

Kinetix VP-Series Servo Motors provide smooth, integrated motion control over EtherNet/IP networks.

Result

Simplifying machine design to meet demand

The new machine has enabled Pacmac to serve a greater variety of products and number of end users. Remote operation and monitoring of the machine is now possible as the multi-discipline architecture can be accessed remotely for troubleshooting or modification, rather than through a physical site visit.

With the multi axis machine, seamless data transfer is possible via Ethernet communication. Based on the product type, end user can select a recipe from the HMI (human machine interface) and system will make an automatic offset adjustment. Operators can more accurately predict and detect failures. Absolute position of the servos can be retained in case of power failure.

End users enjoy higher accuracy and lower maintenance with a reduced mechanical system, and scalability is achievable with axis addition or deletion. It is easy to integrate the machine with upstream systems.

Machine maintenance cost and time is reduced, improving overall equipment effectiveness (OEE). This is accomplished by:

Reducing the number of mechanical parts on a machine, so fewer parts receive extreme wear and tear.

Automating the offsetting of the servo to reduce errors, waste, and downtime.

Reducing product changeover time by simply selecting the product type from the HMI and adjustments are made automatically.

Published April 15, 2024