Since 1953 Senzani Brevetti has designed and built lines for primary and secondary packaging, from cartoners to case packers down to end-of-line systems and palletizers; and from standalone machines to “all-in-one” complete systems.

“Our customers, big multinational companies, prefer us over competitors because of our strong, skilled expertise in the packaging market applications. We support them to achieve their primary goal, which is to improve productivity with maximum safety in their plant. We deliver longer-lasting and more flexible lines, which offer the best processing rate, easier changeovers, and contribute to cutting down waste materials and machine downtimes,” Adele Rava, Senzani Brevetti's Marketing Manager, explains.

Big brand support

The Italian machine builder, which is headquartered in Faenza, in the northern-Italian Ravenna area, works with top-quality brands and support many different markets, including food, homecare, agriculture, tobacco and pet food.

“Innovation and excellent line customization are cornerstones of Senzani's production,” Rava adds. For Senzani innovation essentially means considering the most recent packaging marketing trends – in terms of product package quality (value, strong attention to details, perfection) – and combining them with great processing speed (up to 600 cartons per minute).

Technological revolution

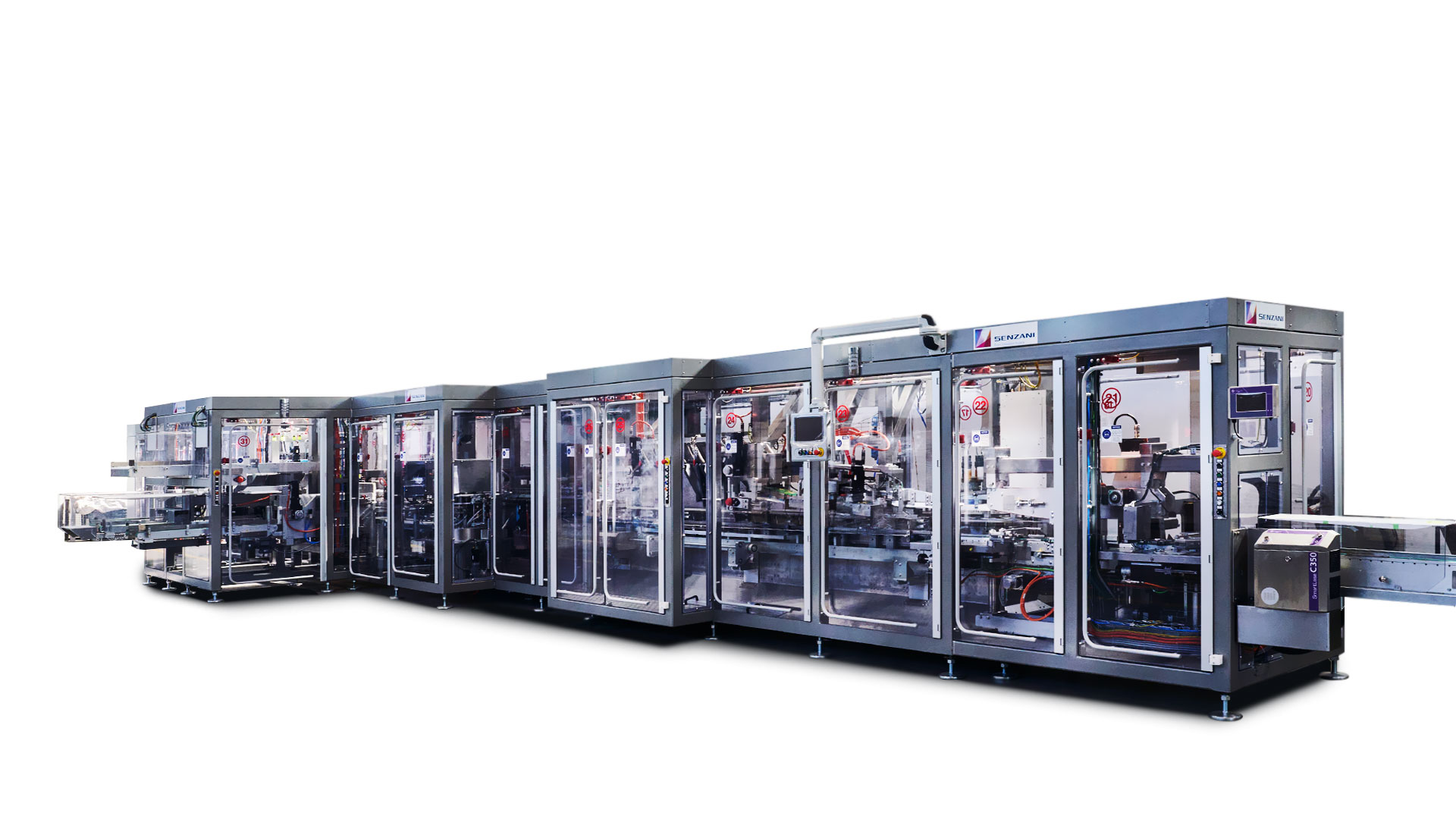

The company’s latest innovation is a new generation of Senzani cartoners, which, the company explains, is a technological revolution capable of supporting customers in the packaging of highly complex and customized packs, with machines that are compact in size and capable of reaching very high speeds.

All this is thanks to the machine’s geometry and the iTRAK® Intelligent Track System from Rockwell Automation, which combines linear and rotary motion, variable pitch, hybrid operation (simultaneous continuous and intermittent motion) and multi-station automatic format changeover.

The machine has already been deployed at a leading US multinational that chose Senzani and its new generation of machinery for a project to convert the pack of its washing machine detergent pods from plastic to cardboard. Senzani's new cartoners allow carton base and cover to be handled with millimetric precision, and, in this case, to be closed with an innovative “click” system, certified for child safety.

Sustainable packaging

Combining minimized and plastic-free packaging, compact machine layout and reduced energy consumption, Senzani's new cartoners stand out as sustainable machines, even in the packaging sector: a market that is paying more and more attention to the environment.

“In our lines, we deploy an accurate combination of working speed and soft handling, to boost product integrity. This combination has always encouraged us to select the best-performing electronic solutions, such as the ones provided by Rockwell Automation, which are a referring standard for automation technology in our machines. Rockwell Automation supports us to be pioneer in innovation, thanks to the excellent cooperation established with its engineering team in developing new projects,” Rava says.

Reduced energy consumption

Standardizing on a Rockwell Automation's platform helps Senzani to reduce wiring effort and hardware and the one-cable servo solutions work to the end-customers' advantage in terms of wiring and clean-design machine layout, offering the chance to replace old pneumatic parts and thus significantly reduce energy consumption.

Furthermore, a big role has been played in this project by the unbeatable support from Rockwell Automation worldwide during product engineering. “In the Bologna area, in Northern Italy, Rockwell Automation established an excellent OEM Application Center, which has supported us in the design of new machine layouts,” Rava concludes. “Rockwell Automation doesn't just give us a piece of software code, but its technicians support us in learning how to use this code and how to develop it on our own, speeding up time-to-market in the engineering of new applications and in problem solving. Rockwell Automation helps us to be more autonomous and quicker in our new business development!”

Discover our comprehensive portfolio of OEM and machine design solutions here.