Functional Safety Standards provide performance requirements for the design, construction, installation, operation, and maintenance of safeguarding when applied to machinery.

One of the more prevalent standards is ISO 13849 Safety of machinery — Safety-related parts of control systems that uses a functional approach to safety. This approach examines the equipment, the materials and the people that interact with the machinery to determine the functional safety requirements for the system.

ISO 13849 also provides safety requirements and guidance on the principles for the design and integration of the safety-related parts of control systems (SRP/CS) for various machinery. It applies to all safety-related parts of control systems, regardless of the type of technology and energy used (electrical, mechanical, pneumatic and hydraulics technologies). It’s a prescriptive standard that specifies methods for determining the performance level required for implementing safety functions and formulated verification methods to establish the performance levels have been met.

Rockwell Automation uses the Safety Lifecycle approach that describes compliant, safe and defensible system designs.

What is the Safety Lifecycle?

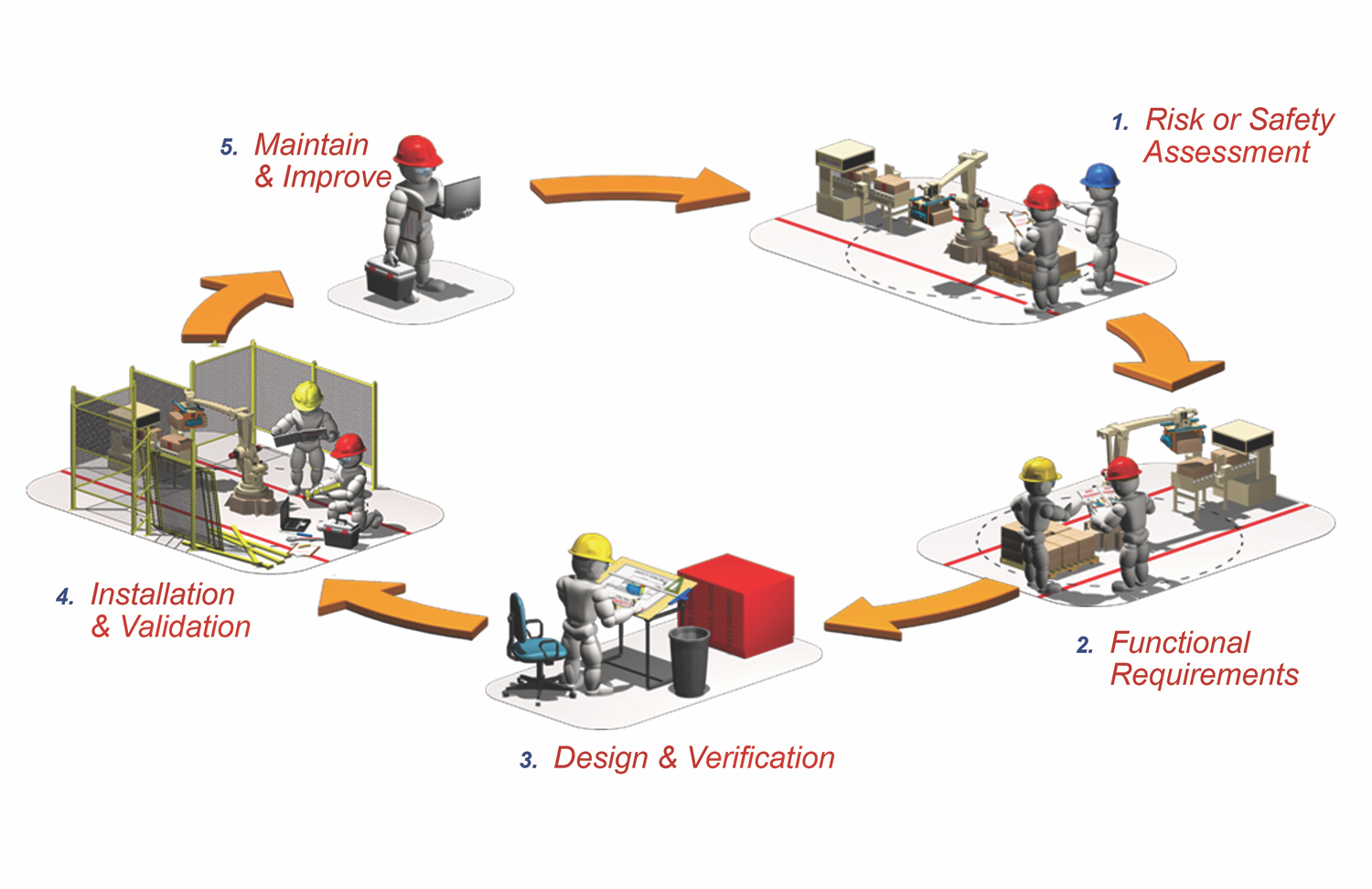

The Safety Lifecycle is a series of phases that helps maximize productivity and improve safety by identifying the steps required to assess and mitigate machinery risks:

- Perform a hazard or risk assessment - Identify hazards and estimate the associated risk. Risk Assessments determine the Required Performance Level (PLr) for each safety function.

- Determine the functional safety system requirements - Evaluate safeguarding options based on industry acceptable solutions and select mitigation techniques.

- Design and verify the system- Design system architecture, document safety circuit design, procure materials.

- Install and validate the system - Verify that systems are operating within defined parameters and applicable standards have been satisfied.

- Maintain and improve the system - Verify that system requirements operate within specified parameters for production and safety preventative maintenance and system upgrades.