This blog post is the second in a series from Kezzler and Rockwell Automation sharing insights from a recent Forrester Consulting thought leadership survey, “Increase Brand Loyalty And Generate ROI With Improved Traceability”.

In an increasingly connected world, digital transformation is an imperative and dynamic process but also a frequent source of disappointment for companies that have not achieved the pace of evolution they’ve sought. The digital transformation journey can be long, varies from industry to industry and is extremely challenging without true data visibility.

While many factors play into the likelihood falling short of digital transformation goals, one of the key hindrances is data – which hinges on visibility. While data poses challenges across industries, its challenges ring true in transforming the face of complex global supply chains and understanding end-to-end product journeys. It is through connected products with unique digital identities and traceability technology that one aspect of digital transformation for the supply chain can be achieved.

Connected Products: Digital Transformation for the Supply Chain Is All About Visibility

Connected products, made traceable with unique digital identities, offer an opportunity to gain unparalleled insight into a product’s entire value chain. Harnessing product data from the journey’s inception to its end offers the ability to improve the consumer experience, remedy diversion and counterfeiting, and support sustainability initiatives. Serialization and traceability technology makes this possible, enabling more comprehensive visibility into the full supply chain.

Visibility is at the heart of what traceability and serialization solutions deliver. And yes, supply chain visibility is still a significant problem for many companies, making already non-linear supply chains even murkier to unravel. According to the Consumer Trust in Social Responsibility Communications: The Role of Supply Chain Visibility report, 54% of companies surveyed by the researchers had no visibility into their supply chain at all. This will have to change. The need to comply with new transparency and sustainability regulations will force companies to shift gears and introduce technology to support visibility. It starts with increased transparency for compliance purposes but can also be leveraged to create more sustainable supply chain operations, measurable environmental impact and carbon footprint, changing business models to establish a more circular economy, practicing better resource efficiency and so on.

The combination of regulatory mandates, need for more sustainable and efficient business practices and consumer demand will require greater transparency and accountability. Brands are exploring digitization and traceability in the form of connected products as a solution to build:

- Transparency and visibility into supply chains, raw materials and finished products

- Pathways to improvement for products, go-to-market motions, innovation and consumer engagement and loyalty

- Trust with verifiable sustainability credentials

- More robust, circular models to do more with less

Digital Transformation Is Driving Changes In Supply Chain Strategies

Although compliance will always be a key driver because it is mandatory, sustainability goals are pushing digital transformation in the supply chain further. In many companies, this change is already underway, while many others have plotted transformation into their near-term strategies. For example, a 2022 study conducted by Forrester Consulting and commissioned by Rockwell Automation found that 57% of those surveyed were implementing or expanding waste-reduction initiatives in the supply chain. 54% percent shared that their companies require suppliers to digitally report against ESG metrics today with another 20% planning to do so in the next 12 months.

Serialization-Driven Traceability

None of this is possible without a clear, value-generating digital transformation strategy that incorporates traceability to provide clear visibility into supply chains and a way to link data from unique products at every step as they travel through the supply chain.

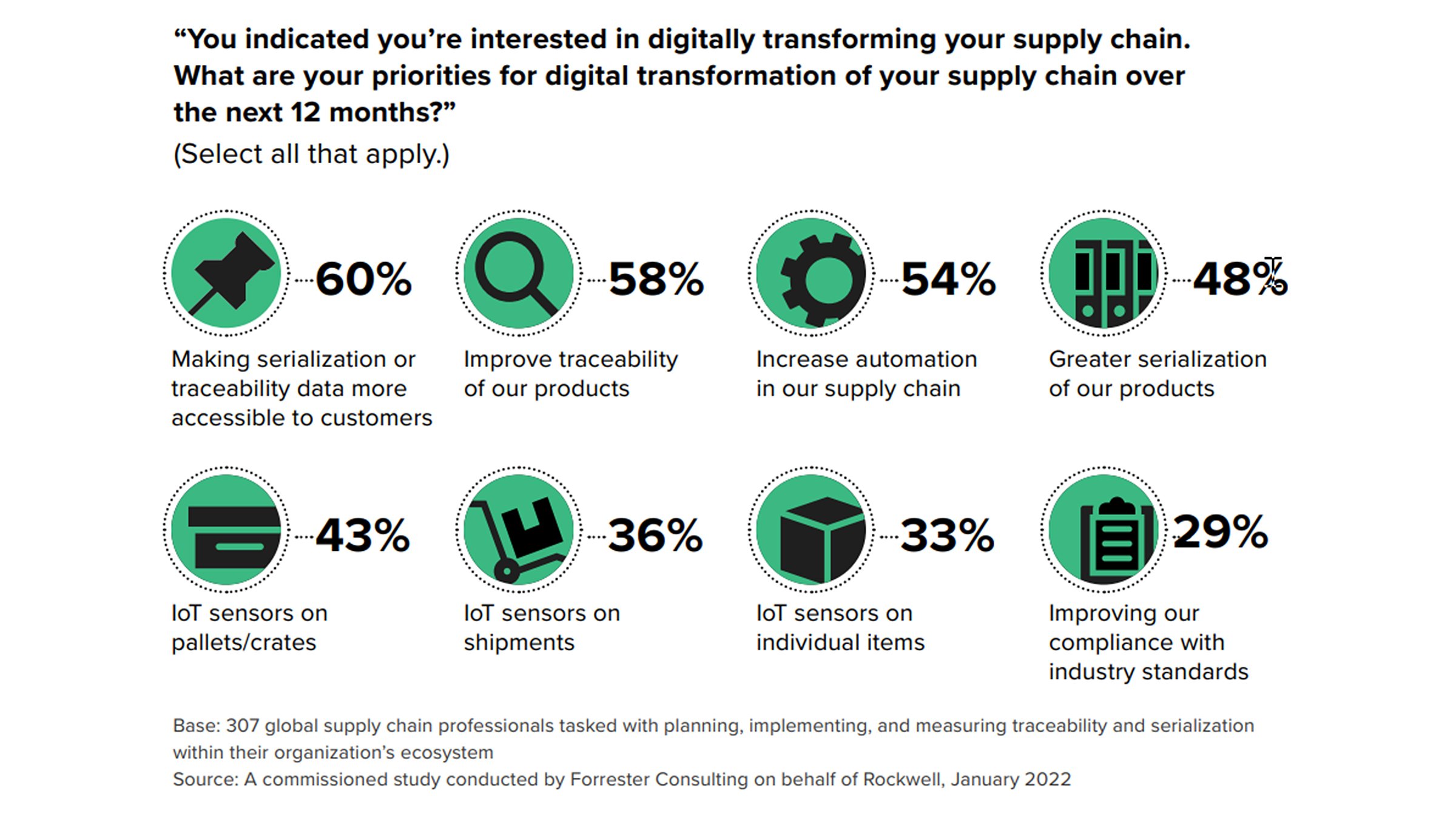

The 2022 Forrester Consulting study commissioned by Rockwell Automation found that companies’ digital transformation priorities align with these needs and with overall business priorities. Survey respondents prioritized the implementation of sustainability initiatives for the supply chain as a top concern alongside visibility into raw material and product sourcing/tracing.

Key digital transformation priorities, according to Forrester Consulting’s findings, include several interconnected imperatives:

- Make serialization and traceability data more accessible to customers (60% of respondents)

- Improve traceability for products overall (58%)

- Introduce greater product serialization to support traceability (48%)