Diverse Industries. Common Goal.

Operational efficiency has long been a primary goal across the industrial landscape. More efficient operations lead to better productivity, less waste – and higher profitability.

Keeping production running optimally has become even more critical as organizations sharpen their focus on reducing their carbon footprint and combatting rising energy costs.

“More and more, customers are coming to us with projects that aim to enhance sustainability,” said Jeremy Meegan, channel sales manager, WIN-911. “And just like any other project, they’re looking to achieve these ‘green’ objectives in the most efficient way possible.”

WIN-911 delivers innovative industrial alarm notification software designed to maximize production uptime, reduce maintenance costs and minimize environmental impact. The company applied its first solution in 1993 and became a Rockwell Automation technology partner in 1998. Currently, the WIN-911 platform is the leading alarm notification software among Fortune 500 companies – and boasts more than 19,000 installations worldwide.

A Tale of Two Challenges

Recently, WIN-911 deployed solutions for two organizations that were keenly focused on achieving environmental goals.

First, WIN-911 was approached by a large university committed to reaching net-zero emissions by 2050. To reduce reliance on fossil fuels, the university planned to upgrade its 90-year-old steam plant and associated piping that connects more than 160 buildings. The new system uses wood chips and renewable natural gas to power turbines – and incorporates a sophisticated heat-recovery system.

WIN-911 was tasked with developing an alarm notification system for the upgrade.

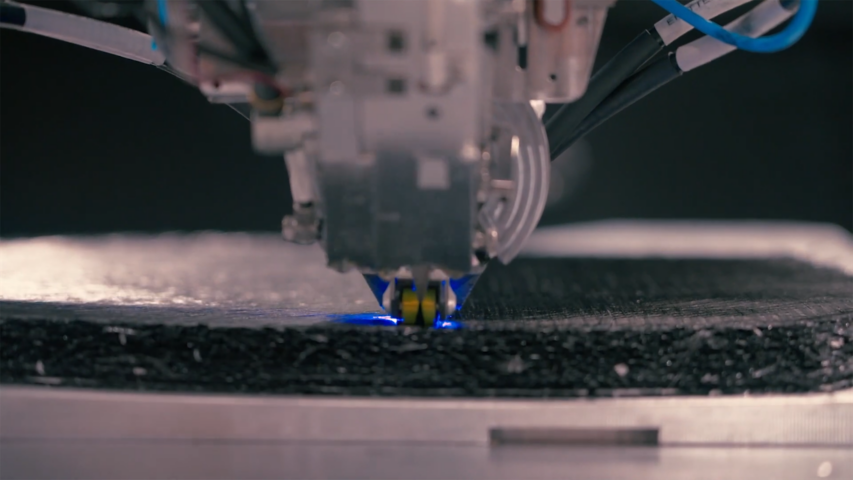

Similarly, WIN-911 was asked to deliver a solution for a Quasar Energy Group wastewater anaerobic digester system. The anaerobic digester breaks down volatile solids in wastewater treatment systems in compliance with regulatory requirements. And also releases biogas, an increasingly important source of renewable natural gas.

“In both instances, having immediate access to the right information if something goes wrong is critical to problem solving,” said Meegan. “Workers can respond to equipment issues more quickly, which keeps overall production goals on track. For example, if an issue with the digester isn’t addressed promptly, the entire process cycle has to restart from the beginning.”

Partnership-Powered Solution

As part of their control system architectures, both the university and Quasar Energy rely on a Rockwell Automation SCADA system, featuring FactoryTalk® View Site Edition (SE) HMI software. FactoryTalk View SE provides a comprehensive picture of production status across entire processes – and a real-time view of operations for multiple stakeholders.

“We partner with Rockwell Automation to deliver a notification system that frees workers from a standard HMI console to enable a faster response,” Meegan said.

WIN-911 software seamlessly integrates with FactoryTalk® Alarms and Events in real time – and leverages properties including alarm severities, tag names, group names and more. The secure notification platform pushes critical alarm and event details to remote workers via mobile app, text, voice or email – on their device of choice.

“We have also developed an advanced escalation workflow feature,” Meegan explained. “This allows users to organize alarm notifications based on type, severity and worker roles.”

More Efficiency. Impressive Outcomes.

WIN-911 solutions enable a faster and more effective response to ongoing equipment and production challenges. Both the university customer and Quasar Energy are reaping the rewards.

At the university, the new hot water heating system is achieving 24% more efficiency than the old steam application. The system is reducing emissions by over 1,000 tons of carbon dioxide annually. And thanks to WIN-911 software, the university can now maintain optimal operation with just one or two operators per shift.

Meanwhile, at Quasar Energy, the WIN-911 system has cut alarm and event response time by 75%.

After completion of the successful model, Quasar Energy implemented the notification solution at two additional wastewater sites.

“Expanding your alarming capabilities is a small example of one thing you can do today to help your operations become more efficient,” said Meegan. “For our customers, the move to sustainability is a long game – and long-term sustainability goals must be factored into any new project.”

Moving Forward Together

WIN-911 looks forward to continuing to work with Rockwell Automation as the two companies advance their technologies.

“We value the Rockwell Automation relationship and continue to stay in sync with the FactoryTalk View product development team,” Meegan said. “It’s a true partnership.”

Sue Burtch, senior commercial portfolio manager of visualization software for Rockwell Automation, concurs: “WIN-911 is a perfect example of how a strong relationship with a technology partner can result in a solution that helps our mutual customers meet their goals. WIN-911 is an outstanding partner.”

Learn more about our Technology Partners.

Published March 7, 2023