Recommended For You

Challenge

- MGE Automation was tasked with deploying a brand new packaging line at a leading producer of cereal bars and snacks. The line had to offer tight integration with existing up and downstream infrastructure.

Solutions

- Allen‑Bradley ControlLogix programmable automation controllers

- Allen‑Bradley CompactLogix programmable automation controllers

- Allen‑Bradley PowerFlex variable-speed drives

- Allen‑Bradley Kinetix servo drives

- Allen‑Bradley PanelView Plus HMIs

Results

- Fully integrated hardware and software solution

- Familiar operating solution along the length of the line

- Reduced wiring with EtherNet/IP network

- Access to real-time manufacturing data

- Access to benefits of The Connected Enterprise®

Background

Westbury, UK-based MGE Automation provides a complete range of mechanical and electrical services backed up by over 40 years’ experience in the packaging industry.

Its customers are those seeking to increase production, replace aging or obsolete equipment, establish brand new production lines or are looking for maintenance and support contracts.

As part of its service it can offer all elements of the project from system & electrical control design, through machine installation and onto maintenance.

In a recent project it was tasked by Dailycer, a leading manufacturer of breakfast cereals and cereal bars for many leading food retailers, to develop and install a complete cereal bar packaging line, comprising conveying of the product from the end of the cooling tunnel, through primary packaging and onto secondary packaging.

Challenge

This was a completely new line at the Dailycer factory, there was no existing system so there was no template on which to base the solution.

Due to the precise supply, mixing and batching processes used in the kitchen system, the new line also had to integrate very tightly to ensure that all elements of the line worked in symphony with each other.

Due to the different components in the line, effective inter-machine communication was also vital.

The row-distribution system had to ‘talk’ to both wrappers and both of the wrappers had to ‘talk’ to a cartoner at the end of the line in order to achieve optimum throughput.

The wrappers also required significant amounts of precision motion, with all axes tightly locked together, another facet that demanded highly accurate communications.

Solution

MGE Automation supplied the major elements of the packaging system for the line, which included conveyors, row-distribution systems, buffers, two flow wrappers, a cartoner and conveyors around check weigher.

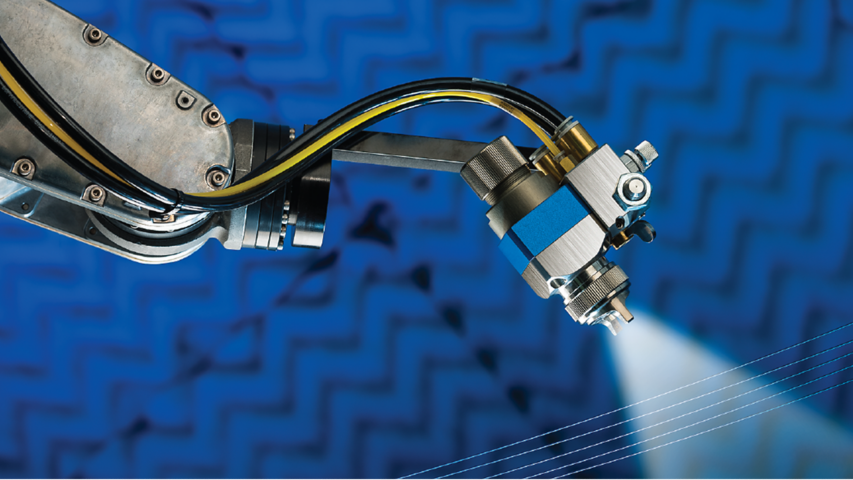

To control this line, MGE turned to Rockwell Automation for its Integrated Architecture® control solution. Primary control products deployed across the line included Allen‑Bradley® CompactLogix™ programmable automation controllers (PAC) and Allen‑Bradley PowerFlex® variable-speed drives on the conveyor systems, a CompactLogix PAC and Allen‑Bradley Kinetix® servo drives on the row-distribution solution and Allen‑Bradley ControlLogix® PACs on each of the two high-speed flow wrappers.

For operator control and interaction, each machine (five in total) is also equipped with an Allen‑Bradley PanelView™ Plus HMI. Completing the primary elements is an Allen‑Bradley Guardmaster®-based safety solution, which feeds all signals back into the primary controllers.

The two (LH & RH) flow wrappers deployed at the Dailycer site were actually refurbished machines that had previously been equipped with a mechanical camming solution for motion.

MGE Automation was able to replace the mechanical control elements with a Kinetix servo-based solution. “We have undertaken these sorts of modifications many times in the past,” explains Mark Gerrish, Managing Director at MGE Automation.

“We have an intimate knowledge of the Logix programming environment and have become very adept at replacing cam-based systems with modern electromechanical hardware solutions driven by the very latest integrated control software.

“The infeed conveyors and the row-distribution solution were both new components, as was the cartoner,” he continues, “but we replaced the controls on the cartoner with the Allen‑Bradley components, which delivered a much more powerful package”

The whole line runs on a Stratix®-switch-managed EtherNet/IP™ communication network – equipped with Allen‑Bradley POINT I/O™ modules – which also offers seamless communication back to the enterprise solutions and the all-important kitchen equipment, which was also based around an Allen‑Bradley solution.

The use of an EtherNet/IP backbone and integrated hardware gives Dailycer the ability to exploit the benefits of The Connected Enterprise®.

Indeed, future plans include the exploitation of real-time manufacturing data in order to make better decisions centred on planning and production metrics.

Results

According to Gerrish: “We have worked with Rockwell Automation for many years. Indeed, we always strive to use Rockwell Automation products as we know they work and do exactly what we need of them.

As a completely new line, this was an interesting proposition as we had a blank canvas in the packaging area and which formed part of a larger blank canvas for Dailycer from the kitchen all the way to the end of the line.

The kitchen system itself is also highly automated with most of it being controlled with Rockwell Automation solutions, including the mixing, batching, temperature control, extrusion, enrobing and finally the cutting with a guillotine.

“The primary benefits to Dailycer in this instance,” he continues, “are based around the capabilities delivered by a connected and integrated control solution.

As well as delivering optimal data paths, the single-platform control solution delivers a familiar look and feel along all elements of the line, from the kitchen all the way through to final secondary packaging.

We certainly hit the throughput and efficiency targets that Dailycer wanted and the line could in fact offer higher throughput if necessary, but this would depend on the product being processed and would need to be balanced with the time required in the kitchen prior to packaging.

The Allen‑Bradley solution offers a simpler and easier upgrade path too, due to its tight integration between hardware and software and its plug-and-play design.

This is of particular importance to Dailycer, which is seeing its order books growing.”

The ability to make better decisions based on real-time production data is a key facet of the Connected Enterprise.

With this data-capable infrastructure, Dailycer will be able to improve productivity and optimise operational performance due to the new insights it now has into its production operations.

Published March 1, 2017