Step 2: Identify Opportunities for Improvement You Can Act on Now. The next step is to discover where you’re spending too much time, money or energy. Here are a few ways you can spot waste in your processes:

- Review specific processes with members of your maintenance team. Ask them what part of the process takes the most time or where they face challenges when completing work. Use this insight to make activities easier and remove roadblocks.

- Identify tasks that consistently take more time or money than planned and conduct a “root cause analysis” to determine why.

- Audit your planned maintenance work to make it more efficient. Question the need for all regular maintenance and the frequency, timing and resources for each task.

- Develop KPIs and metrics around the growth and success of your team. This data will allow you to find wasted potential.

Step 3: Build a Long-Term Vision. Creating a lean maintenance program starts with a lean maintenance mindset. You must ask the right questions, challenge the way you do things, and be willing to change.

Begin by building maintenance activities around business and production goals, and lessen or minimize work that doesn’t connect to these goals.

Next, begin using a proactive maintenance response rather than a reactive response. A lean maintenance strategy hinges on data and taking the time to collect it. Five extra minutes completing extra fields on a work order add up.

Allocate time in your schedule to account for reporting critical data. And inform your maintenance team about the importance of these extra steps.

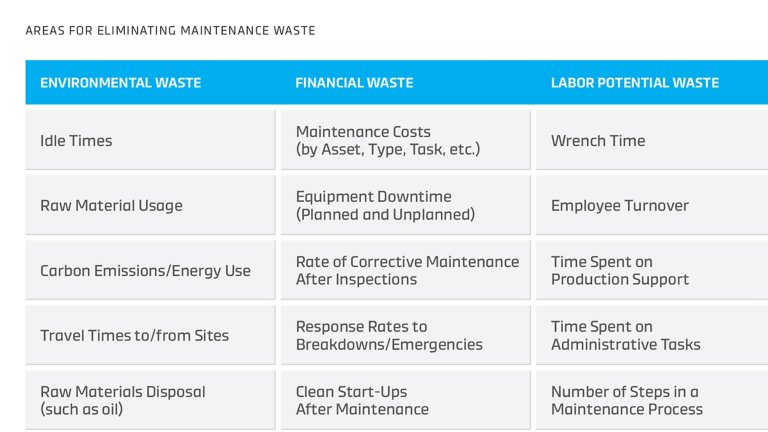

The Table (on the right) shows some best-practice metrics you can start with to address each type of maintenance waste.

Moving from Reactive to Proactive Maintenance

Changing your maintenance strategy from reactive to proactive is a process that begins with small changes over time. But these small changes lead to significant benefits like lower direct costs (labor and resources) and indirect costs (lost revenue due to downtime or lost production). Learn to mark progress with small goals and milestones, track progress and celebrate success.

If done right, it’s a process that’s never truly finished. Adopt a “win-or-learn” mentality instead of a “win-or-fail” mindset.

Allow your team to question the status quo without blame or punishment. You and your maintenance team will see success as a series of small, continuous changes that affect your bottom line and overall performance.

For example, in lean maintenance, a best practice is to examine work orders once a month to reduce delays and increase wrench time by 10% to 15% a year. It’s critical to track progress and celebrate it with your team.

And encourage suggestions from staff on best practices. Technicians will feel a sense of ownership over this metric and will be invested in achieving progress.

Using a CMMS

A modern computerized maintenance software (CMMS) solution is a best practice for achieving lean maintenance. It can help you execute on lean maintenance to increase efficiency. Removing unnecessary work and administrative tasks helps employees feel more engaged with their work. It also gives them time to train and perform high-value work.

Maintenance and Business Needs

At its core, lean maintenance is about tying maintenance practices to business needs. It’s a critical step to move maintenance from a cost center to a value driver. And when accomplished, the maintenance team becomes a true business partner.

Like this article? Sign up for the digital magazine from The Journal From Rockwell Automation and Our PartnerNetwork and get articles like this delivered right to your inbox.

The Journal From Rockwell Automation and Our PartnerNetwork™ is published by Endeavor Business Media.