By Sandy D’Souza, Director of Product Marketing at Fiix, by Rockwell Automation

World-class manufacturing is often defined by the smallest of measures. An extra few minutes of uptime on each shift could be the difference between completing an order on time or not. A slightly misaligned component can lead to a massive breakdown and hours of lost production.

Hundreds of decisions are possible for manufacturers to make every day on each asset. Each decision comes with an opportunity to make these assets, and every input that goes into its performance, more efficient. Although each opportunity may be small, it can lead to outsized value in the form of doing more, wasting less or reducing risk.

Finding and accessing these incremental gains can provide a massive competitive advantage for companies, especially in an industry where the playing field is often so level, and macroeconomic factors, such as inflation and broken supply chains, pose massive external threats.

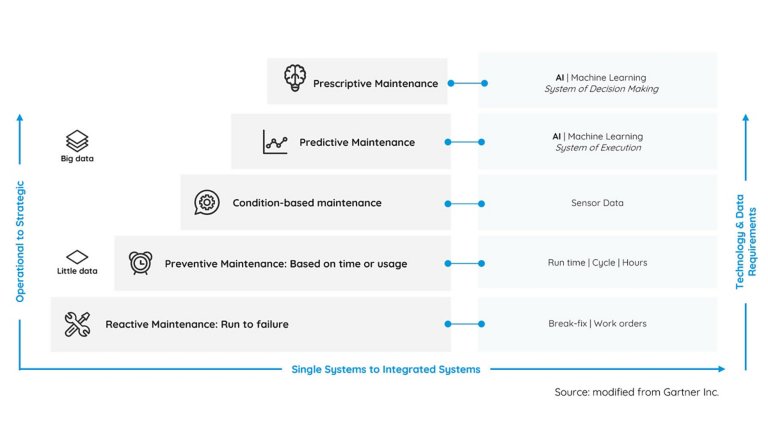

Capitalizing on these opportunities at scale is challenging. Data is the key ingredient that makes it possible. And there lies the next great leap forward in asset performance management (APM) — using data to spot opportunities to improve asset function, then assess which opportunities bring the most value and how to execute these plans with the least amount of risk.

“The future of APM strategy is the democratization of data,” says Michael Hart, director of product strategy, Manufacturing & Industrial IoT at Rockwell Automation.

“It’s the combination of advanced algorithms and accessible, out-of-the-box systems that allow people to use these algorithms to make data-driven decisions without massive investments, learning curves and manual work.”

Big Data, Small Gains, Huge Potential

Professional auto racing offers manufacturers a glimpse of how data can be used to capture a competitive advantage through minor improvements. In the early days of the sport, teams relied on basic analytics to make decisions. Race strategies were based on data such as the ideal number of tire changes or the dimensions of the car.

The data, and how it’s used, has evolved rapidly since then. Now, teams run millions of simulations to test every possible factor before each race, from which tires to use during rainy conditions to how much fuel to use in cold weather. This is coupled with up-to-the-second data collected during a race to make real-time decisions. In a sport where milliseconds can determine a winner, these small advantages can push one team to the top.