By Ryan Klemetson, Business Development Manager, Tolomatic, Inc.

With ever increasing demands to control costs while achieving high speed and high precision in industrial automation, it’s best to fully analyze a linear actuator application and precisely determine a project’s parameters. This is especially true with electric rod-style actuators because of their higher initial cost, more complex design and more predictable performance compared to fluid power cylinders.

Additional engineering and analysis at the front end of an electric actuator application will help reduce overall costs and help provide higher reliability, better performance, lower energy costs and less maintenance. Here are four tips to help you.

#1: Calculate loads precisely.

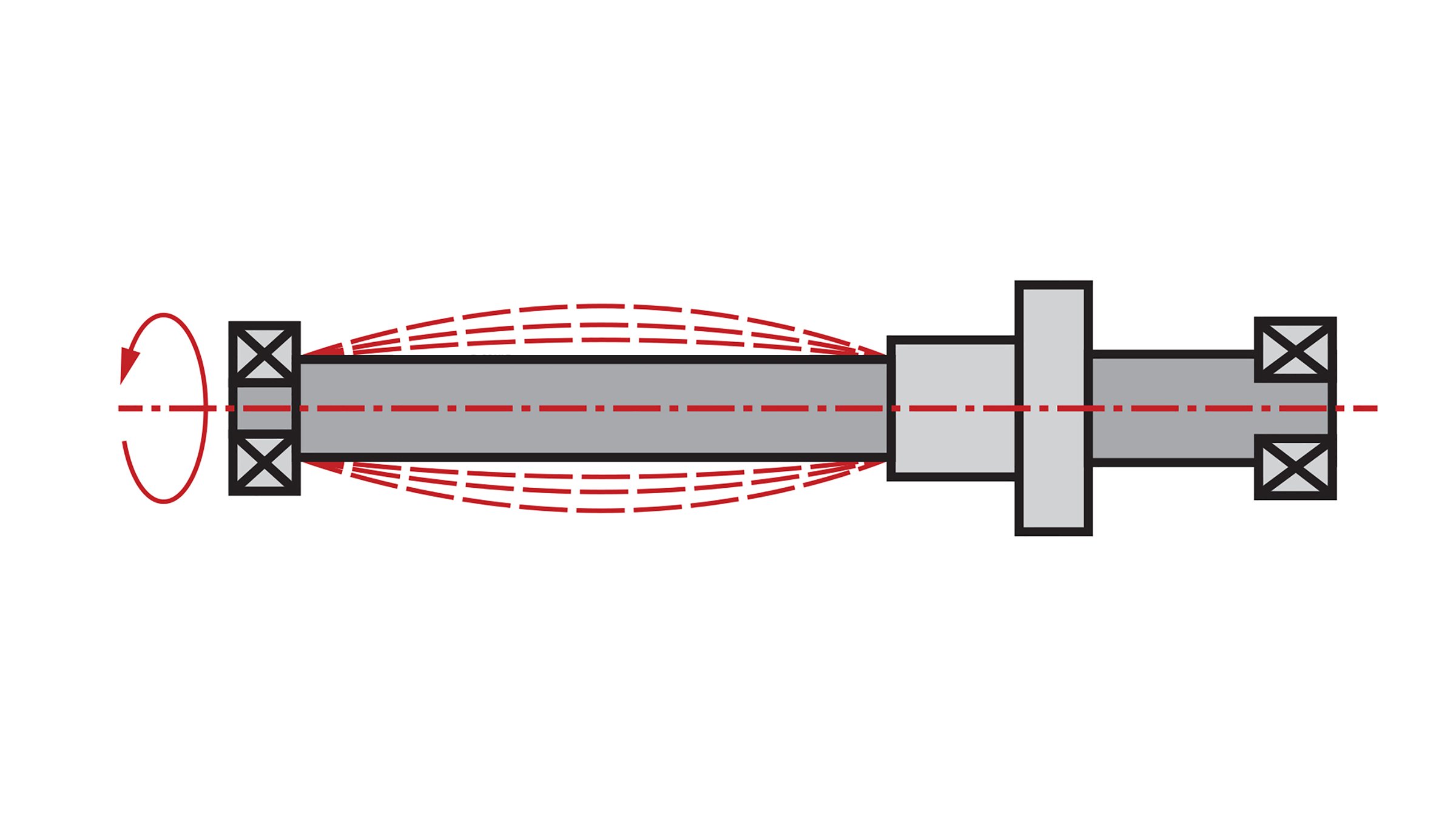

The ability of an electric rod-style actuator to perform its intended task with accuracy, speed and durability depends on matching the electric motor, the lead screw and the bearings to the anticipated loads. By knowing the precise static and dynamic loads of the application and matching them to the actuator’s peak and continuous load capabilities, the application will be both cost-effective and reliable.

#2: Calculate for electric, not fluid power (pneumatic or hydraulic).

Oversizing actuators is a habit carried over from fluid power applications in which oversizing was inexpensive insurance against not having enough power. With fluid power cylinders, the additional cost of a slightly larger bore size than required was minor compared to the extra engineering time that might be involved in sizing it correctly.