Italian end-of-line packaging specialist Cama Group is a great example of a company that listens to its customers and then delivers a solution that fits their precise needs, as opposed to developing a close match from a restrictive range of technologies.

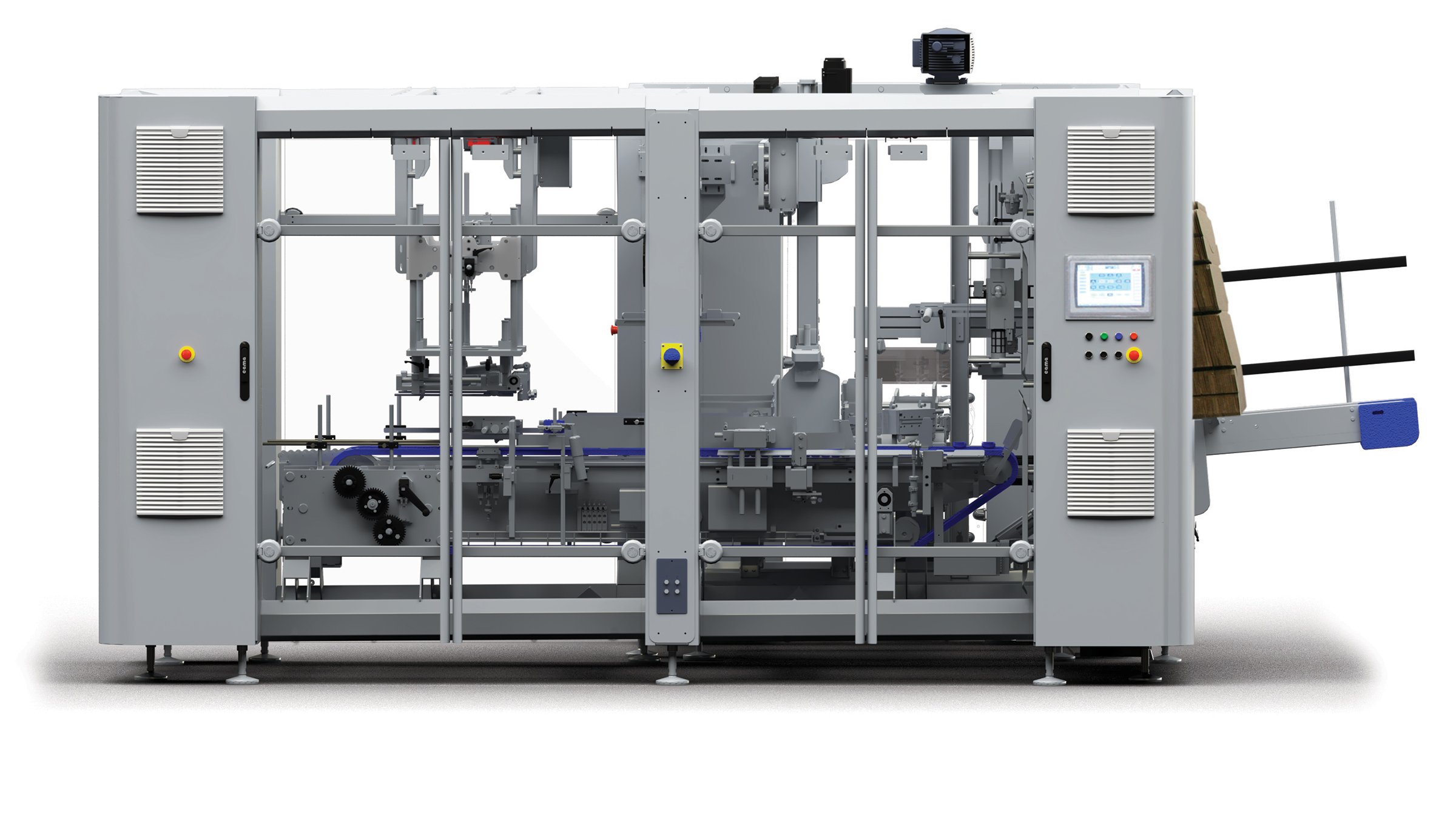

This capability is due to Cama perfecting multiple packaging approaches and its experience from serving so many markets, products, and packaging styles. To maintain this position, Cama has to ensure that its mechanical, electro-mechanical and electrical systems are as agile as possible – to address myriad packaging possibilities.

The power of partnerships

According to Filippo Aspesi, Software and Automation Manager at Cama Group: “As a Gold OEM Partner in the Rockwell Automation PartnerNetwork™, we are very fortunate to have a strong relationship with the company’s technical team in Italy. We are often called upon by customers to develop interesting solutions, those outside the realm of what you might class as ‘normal’ packaging, so a close relationship with our automation supplier really helps.

“Every year the Rockwell Automation Italy team presents us with new technologies and descriptions of what is in the pipeline,” Aspesi explains. “This allows us to look to evolve our automation solutions based on new capabilities. One example being a new drive family, which we are currently evaluating. We are also looking at a new safety system, which simplifies connection and configuration.

Game-changing flexibility

Aspesi explains how Intelligent Track Systems are gaining favor too. “Our customers really recognize the potential of iTRAK and MagneMotion. Both are game changers for machine and process agility. They’re not suitable for every application, but our experience of the technologies and our work with Rockwell Automation mean that we can suggest and specify them where they will be the most effective solution to a customer’s challenges.”

A recent project that required maximum agility from Cama’s machines was for Hawaiian Host, a leading North American confectionary company based in Honolulu. The turnkey line Cama developed is designed to delicately handle naked chocolate products, in three different shapes and then package them in an array of different counts (15), packaging formats (17), and SKUs (5) – all at a throughput of 1,500 ppm.

With third-party laser-based vision systems and specialist pneumatic grippers, the machine illustrates current state-of-the art in terms of volumes, product variation and machine flexibility, thanks to a perfect amalgamation of Cama’s machine and hardware design and a tightly integrated automation architecture from Rockwell Automation.

Never be the weak link

Cama’s Group Sales Director, Alessandro Rocca, explains: “This is a fantastic deployment of our entire package, from mechanical design, through advanced electromechanical automation solutions from Rockwell Automation, and onto AR and AI to deliver even greater efficiencies and ease of use. The confectionary industry demands maximum efficiency and, as a solutions provider, we have to make sure that none of our technology, including that from our suppliers, is a weak link in what is a much bigger process. In fact, in the majority of applications our machines tend to be governed by up- and downstream processes. It is our goal to never limit line speed in any industry.”

Continuous improvement

And these efficiencies are being continually tweaked, as Aspesi adds: “There is so much continual development work going on ‘under the hood’, much of which our customers don’t know about. With the help of the Rockwell Automation team, we are changing the logic and the trajectories of our in-house developed robots. You can’t necessarily see the modifications, as many of them are very subtle, but if you evaluate the performance, you will discover that they are actually running faster.

“Expanding on this,” he concludes, “our motion and axes development is now much easier too, as the latest version (V.35) of Studio 5000 Logix Designer® software allows us to fully virtualize all axes in the new axis test mode. This makes a big difference to our design procedures, as we can now simulate, stress, and refine complete systems before putting them in the machine. Rockwell Automation really is at the top of its game when it comes to technology and support!”.

For more information about the Rockwell Automation PartnerNetwork, click here.