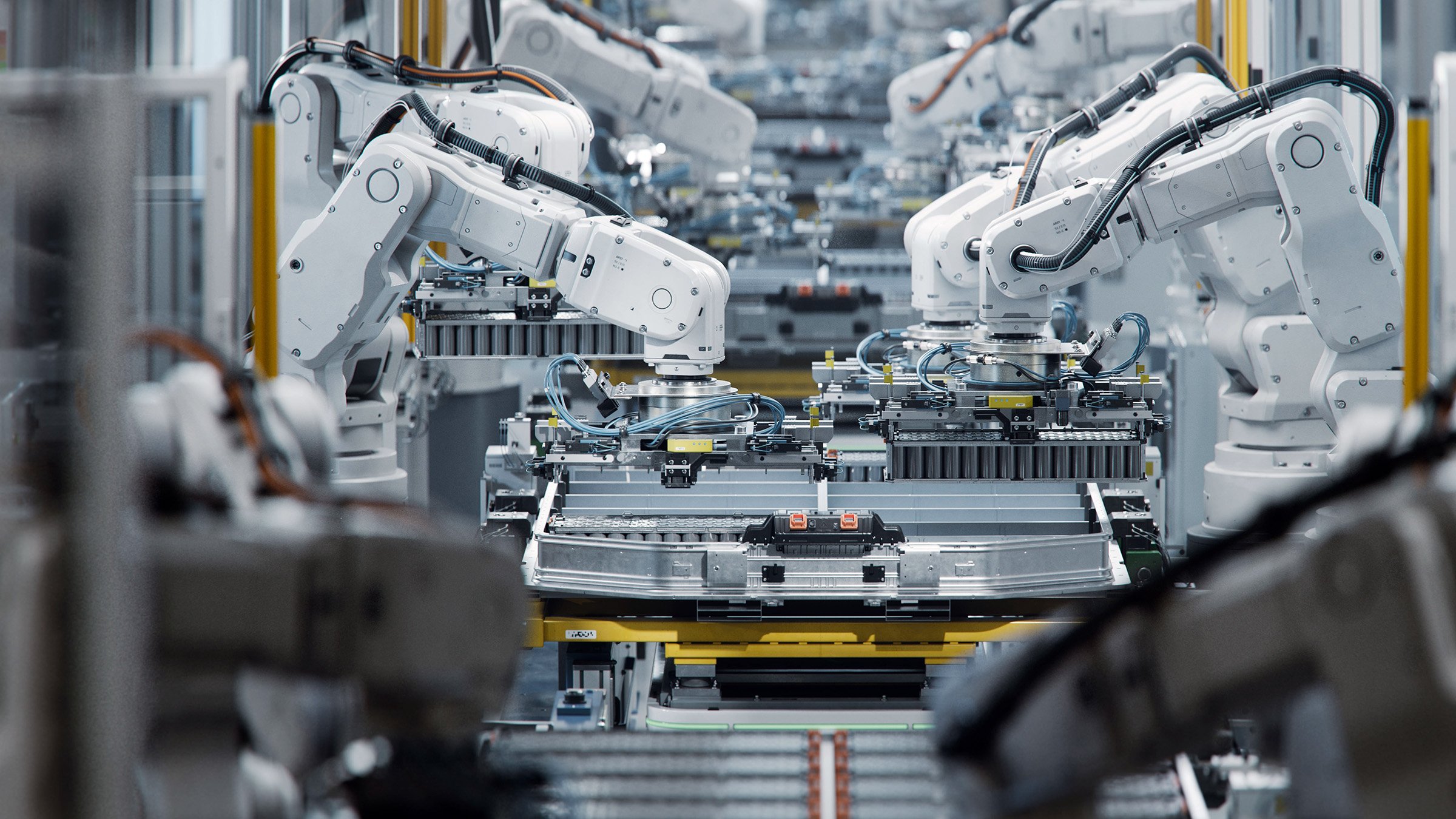

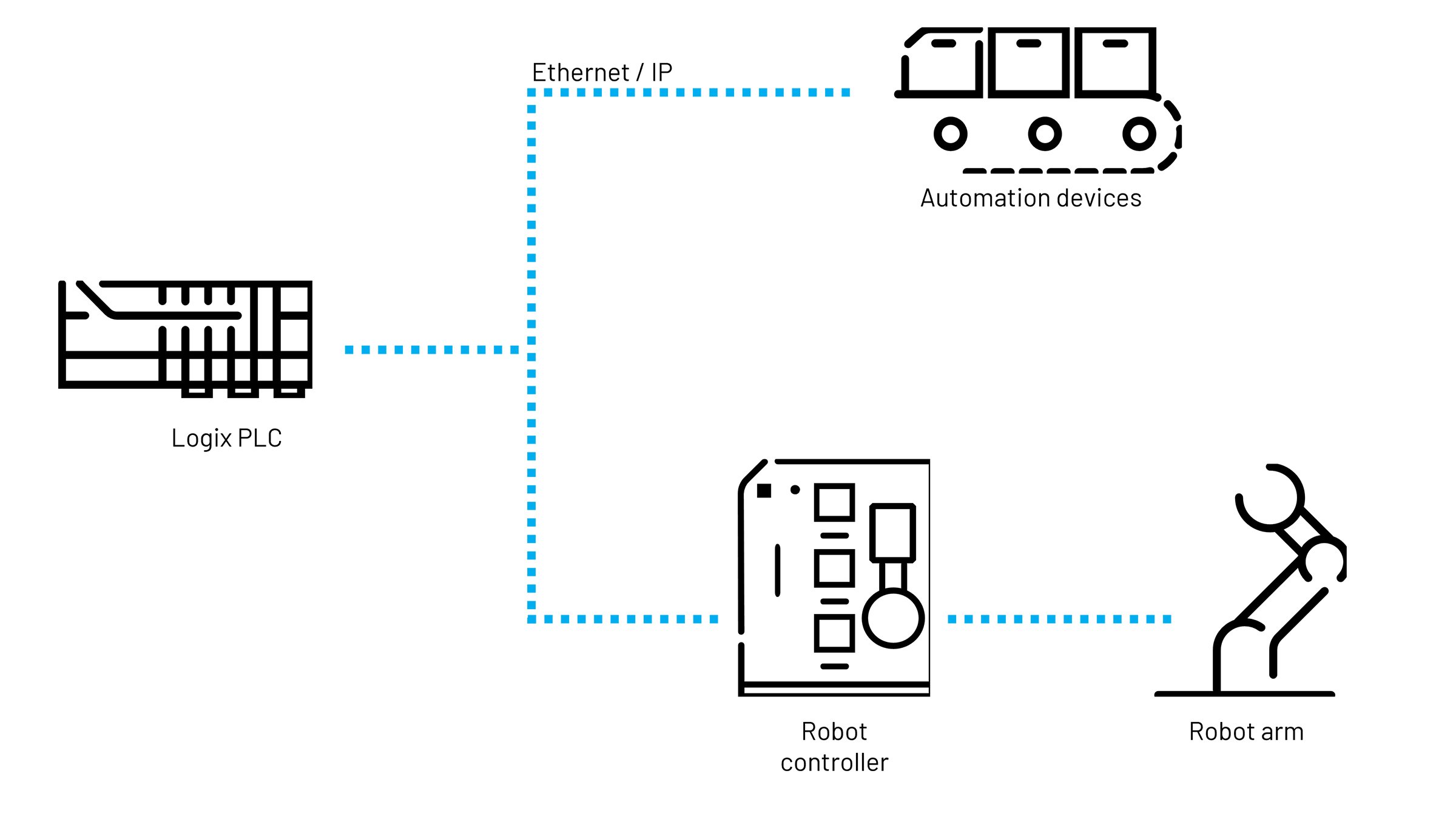

Your robot automation systems are critical to improving flexibility and maximizing production efficiency, but to deliver the most value, they must be better connected with your production systems. With our EtherNet/IP connected robot solution, you can effortlessly bring robots into your control network with a simple, single cable connection that simplifies control and helps unlock the power of data in your systems.

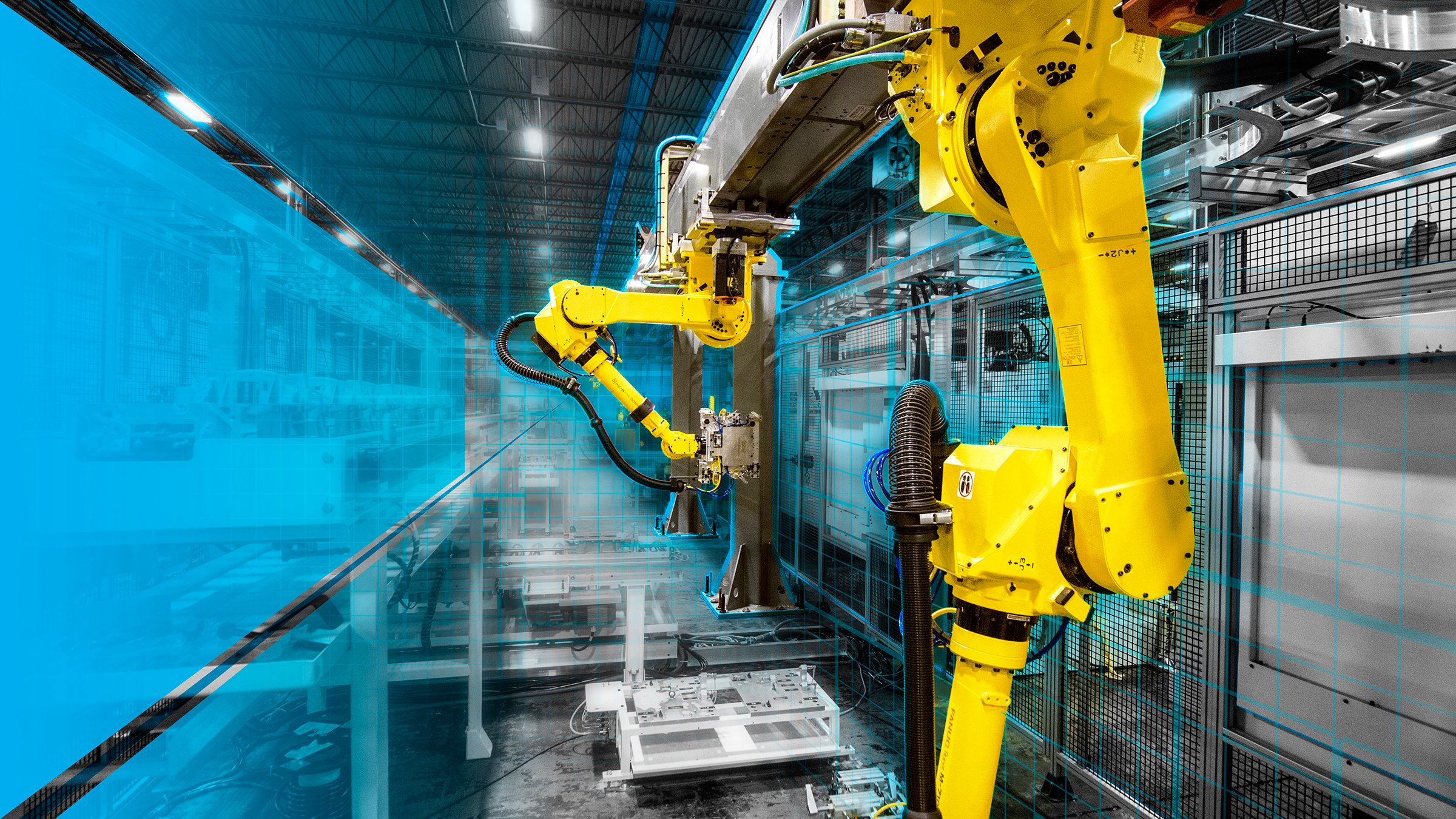

With better connected robots in your facility, you can:

- Create new efficiencies and scale them across your production

- Empower teams with simplified designs and standardized workflows

- Harmonize operations using data visibility and interoperability between software solutions