Industrial Smart Devices

Allen-Bradley Smart Devices are an integrated, scalable solution, offering new efficiencies and reduced total cost of ownership.

Smart Devices improve product quality, reduce downtime, and future-proof your investment in smarter machines to allow smarter manufacturing.

Smart Safety enabling smarter machines and equipment

Harnessing the power of safety and operational data can substantially improve safety compliance and performance. Accessing safety system data and transforming it into meaningful information results in increased machinery productivity, and minimizes downtime.

To gain more diagnostic data traditional safety devices required more complex wiring solutions. With a Smart Safety solution, you can now access more diagnostic data and simplify your wiring system.

An integrated Smart Safety solution provides all the data needed to create a comprehensive picture of the status of the machine or production line.

Challenges to safe operations

Worker behaviors

- Operators bypassing poorly designed safety systems

- Systems that don’t account for procedural anomalies

- Standard operating procedures not being followed

Evolving workforce

- Safety implications of major workforce shift worldwide

- Older workers nearing retirement at higher risk of musculoskeletal injuries

- Younger, less experienced workers more prone to injury

Machinery downtime

- Downtime for jams, misfeeds, adjustments, changeovers and maintenance

- Minimal visibility of downtime information

- No context of downtime issues (workers interaction, machinery fault, shift patterns)

- Limited information to remedy issues

Regulatory compliance

- Compliance with industry standards can be challenging

- Documenting and reporting on approved safety systems can be challenging

Data management

- Continuing reliance on outdated data collection and reporting methods

- Safety data often manually entered for inspections, compliance logs, incident reports, training and other processes

- Systems in which data is stored typically not connected to plant floor systems

Smart Safety at work

Access to real-time data and seamless connectivity is transforming the production environment. Smart capabilities enable end users to gain new efficiencies, improve product quality and make operations more responsive. Smart Safety helps to standardize machinery and safety control. These systems are less susceptible to nuisance shutdowns and can help to improve productivity and profitability.

Smart Safety devices

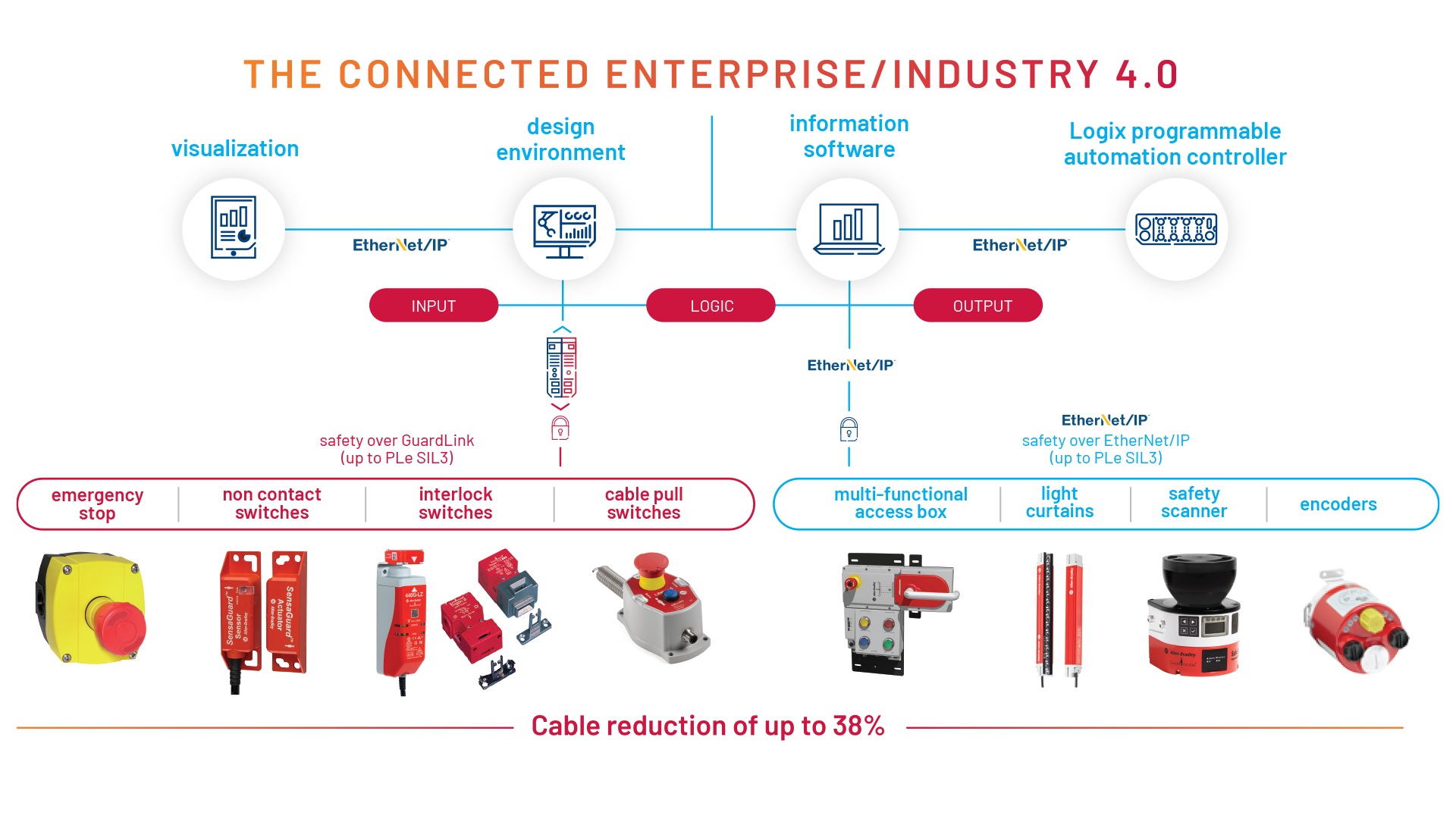

Smart Safety solutions provide detailed diagnostic data to your design environment, visualization system, information software, and GuardLogix® Programmable Automation Controller – enabling Smart Machines for Smart Manufacturing and helping to increase productivity and minimize downtime while reducing total cost of ownership.

Smart Safety enables Smart Machines for Smart Manufacturing

A solution incorporating Smart Safety devices enables safety professionals to transform the way they monitor and manage safety. Rockwell Automation provides a complete Smart Safety solution to meet safety requirements, covering safety input devices, safety logic, and safety output devices.

Benefits of a Smart Safety solution

Improve insight into worker behavior and compliance

By incorporating safety information into EHS management systems, day to day discrepancies between policies and operating procedures can be identified.

Enhance safety

Connecting people, equipment and worksites create new opportunities to enhance worker and environmental safety, including remote access, operations visibility, worker location and information delivery via mobile devices.

Reduce safety-related downtime

Better visibility into safety-system performance and stoppages can help determine the root cause of shutdowns. Safety and production data also can be combined to understand the frequency, duration, time and location of safety-related shutdowns.

Improve compliance

The safety data required for compliance and reporting purposes is largely collected through time-consuming, error-prone manual audits today. By integrating auditing functions into the HMI and controller, organizations can automate and speed up the auditing process, free up personnel to focus on other priorities, and reduce the likelihood of errors.

Application Scenario 1 of 5

Remote troubleshooting with Smart Safety

Safety device performance communicated over EtherNet/IP

Predictive maintenance routines established from historical data

EtherNet/IP network allows standard and safety data to be captured on individual device operation

Simplifies wiring and system complexity

All time stamped data of device operation available in FactoryTalk® Historian

Application Scenario 2 of 5

Request safe access over EtherNet/IP network

Guard position, lock status and access request managed over standard unmodified ethernet (Safety over EtherNet/IP)

Historical data of access request can be used for application adjustments

Simplified network architecture for standard and safety control

Add-On Profile (AOP) in Studio 5000® provides simplified setup and monitoring

Indication given separately for guard door position and guard lock status

Application Scenario 3 of 5

Machine uptime from Smart Safety data

Access frequency into the machine through individually identified access points is available with Smart Safety

Smart Safety allows data to be captured on individual device operation

Simplifies wiring and system complexity

Smart Safety can be used with your existing safety devices

Historical data of access request can be used for application adjustments

Application Scenario 4 of 5

Predictive maintenance with a Smart Safety solution

Smart Safety allows predictive maintenance procedures to be adopted based on device use or age

Smart Safety allows data to be captured on individual device operation

Simplifies wiring and system complexity

Smart Safety can be used with your existing safety devices

Historical data of access request can be used for application adjustments

Application Scenario 5 of 5

Reduce downtime with a Smart Safety solution

Smart Safety solution helps production uptime with warning and diagnostics information

Reduced system complexity enables simpler maintenance and flexibility to change

Pro-active maintenance can be scheduled to avoid issues

Historical data on individual safety devices can be used for application adjustments

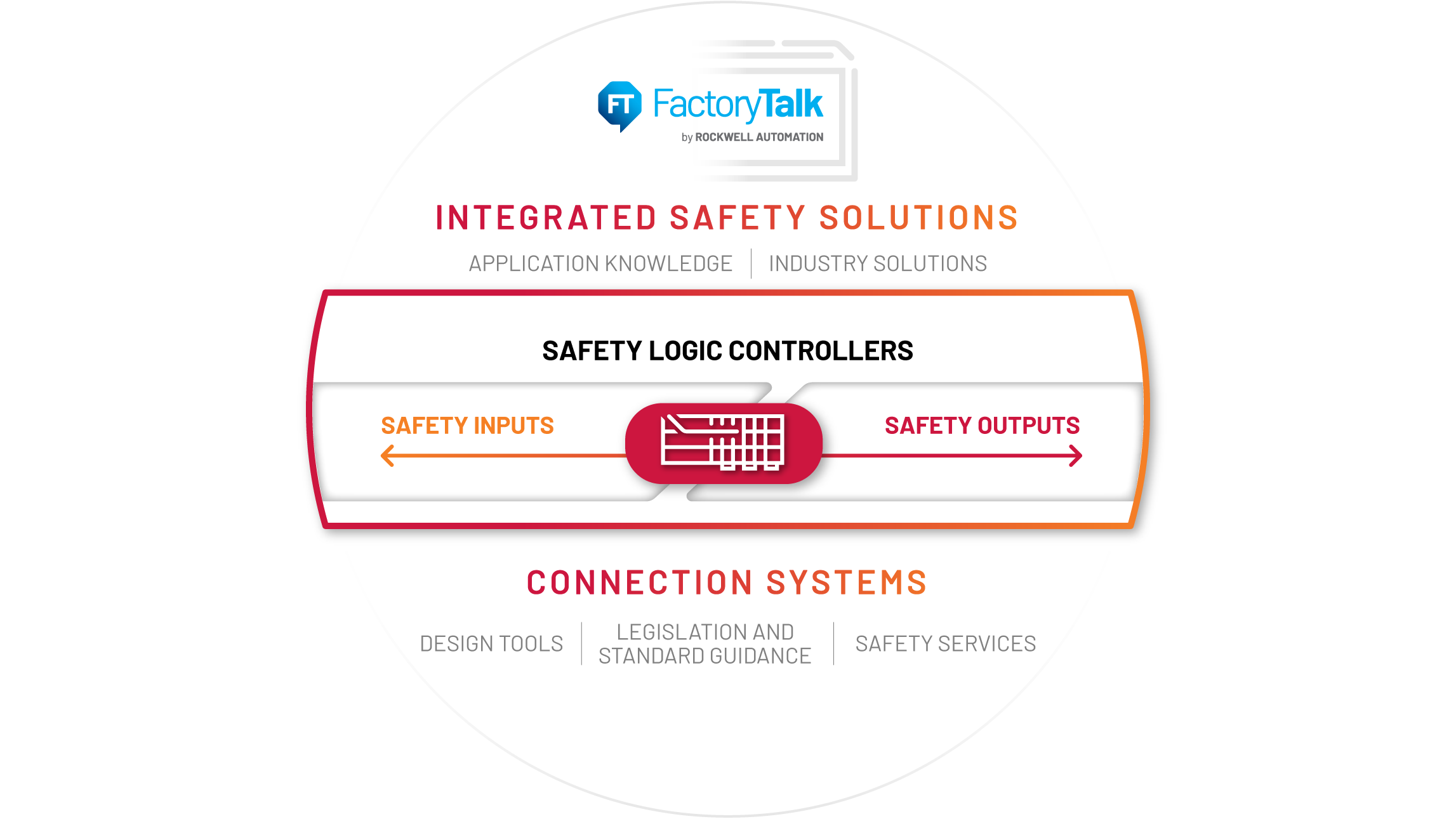

3 pillars of support for your safety requirements

Pillar one

The right products

Rockwell Automation has the broadest portfolio of any machinery safety solutions supplier, and can provide all three parts of a safety system.

Safety input devices

• Presence sensing safety devices

• Safety interlock switches

• Emergency stop and trip devices

• Operator interface

Safety logic controllers

• Safety relays

• Configurable safety relay

• Integrated safety controllers

• Safety I/O devices

Connection systems/networks

• ‘Quick connect’ connection systems

• Safety over EtherNet/IP

• GuardLink™ linking technology

3 pillars of support for your safety requirements

Pillar two

The right people

A comprehensive range of safety services and support is available from both Rockwell Automation and its machinery safety certified ‘Recognised System Integrator’ partners.

TÜV Rheinland certified machine safety training courses

Helping deliver staff training that qualifies towards an industry-standard TÜV Rheinland Certificate, enabling trainees to understand safety requirements and compliance.Risk Assessment Service

The global safety team of consultants and partners from Rockwell Automation can assist end users, integrators and OEMs at any step of a safeguarding project. Comply with safety standards to reduce the risk of injuries and improve productivity.

Trained staff and partners

Rockwell Automation has TÜV Rheinland machinery safety qualifications it requires its employees and partners to achieve in order to support you. Leverage their knowledge now.

Knowledge of automation and safety

The benefit of partnering with Rockwell Automation is you gain the support and expertise of people who understand automation and safety, not just safety.

3 pillars of support for your safety requirements

Pillar three

The right tools

A wide range of tools that support compliance with safety standards, reduce the risk of injuries and improve productivity.

Safety Automation Builder

FREE software tool to help simplify machine safety design and validation, reducing time and costs. Integration with RASWin Risk Assessment Software provides you with consistent, reliable, documented management of the Functional Safety Lifecycle.SISTEMA integration

The SISTEMA tool automates calculation of the attained Performance Level outlined in (EN) ISO 13849-1. Data is available to be used with the SISTEMA calculation tool.

• Helps users in the design stage

• Comprehensive Rockwell Automation database

Pre-engineered Safety Functions

Machine safety can be developed by combining blocks of safety functions. Our pre-engineered safety functions come with a SISTEMA Performance Level calculation as outlined in (EN) ISO 13849-1.

• Reduces design times

• Includes set-up, wiring, configuration, and validation information

• Complete bill of materials

Accelerator Toolkits

Easy to use system design, programming, and diagnostic tools to assist in the rapid development and deployment of safety systems.

• Reduces design time and risk

Adopt a Smart Safety solution today

Allen‑Bradley® Guardmaster® smart safety devices that feature GuardLink technology deliver information, advanced functionality, and flexibility. This technology helps enhance safety and increase machine- and plant-wide efficiency.

GuardLink technology enabled devices offer advanced features and diagnostics that can only be accessed through a GuardLink enabled connection tap. The benefits of GuardLink technology include:

• Real time, contextual diagnostics and sensor health data significantly improve troubleshooting

• Automatic Device Reset (ADR)

• Seamless integration into Rockwell Automation EtherNet/IP™ architecture

Others also viewed

Based on your activity