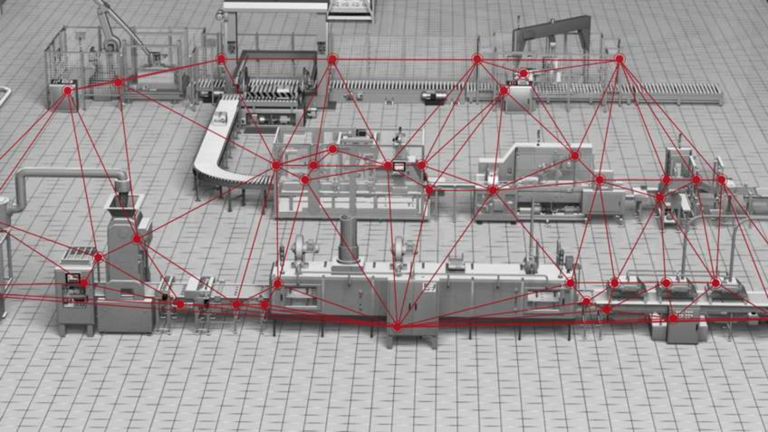

The rapid evolution of technology in industrial automation systems requires tighter integration between devices on the plant floor and the rest of the enterprise. This integration requires a secure network infrastructure, smart devices for efficient data collection, and the ability to turn data into actionable information.

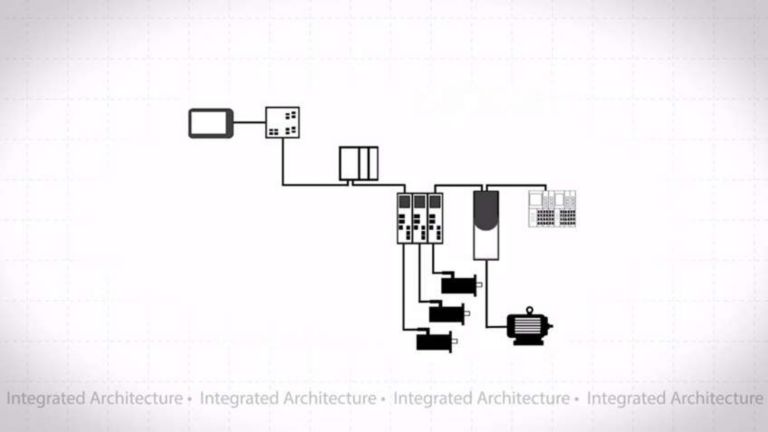

The integration of control and information across the enterprise enables our customers to optimize their operations by connecting the plant, site, facility, and people. We deliver industrial automation and control through our control systems, motor control, and smart devices portfolios. The combination of these three platforms are architected and designed to help you build the most efficient industrial automation system to meet your needs.