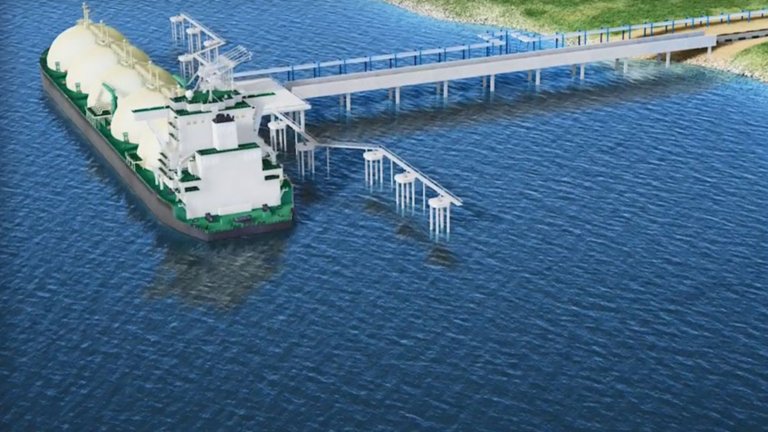

Tight controls are required for liquefied natural gas (LNG) liquefaction, regasification, and shipping/receiving. It is crucial to maintain a safe working environment, minimize downtime, and manage operational costs. To achieve these goals, your automation systems must meet stringent process control requirements, and also be reliable and scalable.

Integrated Systems for Safe, Optimized LNG Plants

While LNG offers substantial rewards, it also poses significant challenges. Tough environmental and safety regulations mandate constant vigilance. Volatile markets demand agile responses, and dynamic business conditions require operational excellence.

Our integrated systems and services enable smooth data flow at all levels and can offer a complete automation solution. Rockwell Automation and our PartnerNetwork™ associates have proven solutions to help you satisfy demand and maintain a competitive edge. We acknowledge that multiple technologies and devices are required to operate your plant. Our solutions integrate process control, motor control, safety, and information technologies.

Our open systems approach makes it easier to integrate equipment from multiple vendors into a single control system.

Explore Operational Excelence in Liquified Natural Gas

Achieving operational excellence in oil and gas midstream operations involves electrification, remote monitoring, and digital capabilities. Electrifying processes reduces carbon footprints and boosts efficiency. Remote monitoring enables real-time data collection for proactive maintenance and minimized downtime. Digital tools like advanced analytics and machine learning provide actionable insights, optimizing performance

and safety.

Efficient and Safe Liquefaction Operations

Sensia-delivered Solutions

Sensia, a JV created by Rockwell Automation and Schlumberger in October 2019, has a team of knowledgeable engineers and project managers who understand your issues. By taking advantage of easy to use tools and modern technology, they design solutions that help you meet plant production goals. Sensia has helped global customers seamlessly migrate their less effective control systems, update safety systems, and optimize processes by using advanced process control solutions.

Sensia also provides various engineering services that can help you reduce risk while helping keep projects on time and on budget.

Sensia’s integrated information, control, and power solutions for the liquefied natural gas industries are suitable for:

- Fire and gas systems

- Motor control solutions

- Metering and measurement

- High integrity pressure protection systems

- Process safety, which includes emergency shutdown systems and safety instrumented systems

- Pump, compressor, turbomachinery control and condition monitoring

- Process and Advanced Process Control

Process Control Solutions for Optimized Operations

Automating your processes does not have to be a “one-size-fits-all” solution to maintain your critical operations.

Today, process control, discrete control, power control, and safety control no longer have to be a choice of separate technologies. Producers can now choose to implement a plant-wide control system. The use of common automation technologies enables seamless integration of our process control system with plant-floor and business systems, creating more opportunity for plant-wide optimization. This approach improves productivity, lowers energy consumption, and reduces total cost of ownership.

Our optimization solutions help you meet the variability, waste, and energy consumption challenges you face to help you meet your production goals. We manage this through our unparalleled industry expertise and in-depth knowledge of the key processes and variables that can be improved to help you meet your business objectives.

Our process control and optimization solutions can help you in areas like:

- Operational safety

- Cost of maintenance

- Reduced fuel and power usage

- Environmental regulations

- Optimal separation of fractionated products

Increasing Performance with a Single Modern DCS

LNG Ships Benefit with Improved Energy Consumption, Increased Productivity

The owners of the LNG Portovenere and LNG Lerici knew their ships were midway through their lifecycle. They also knew they were challenged with having two control systems. Other equipment like boilers, pumps, and turbines were also in their project scope. They sought out a partner to help guide them through a modernization and chose Rockwell Automation to help. Learn more about their challenges and the results we were able to help them to attain.

Recommended for You

Others also viewed

Based on your activity