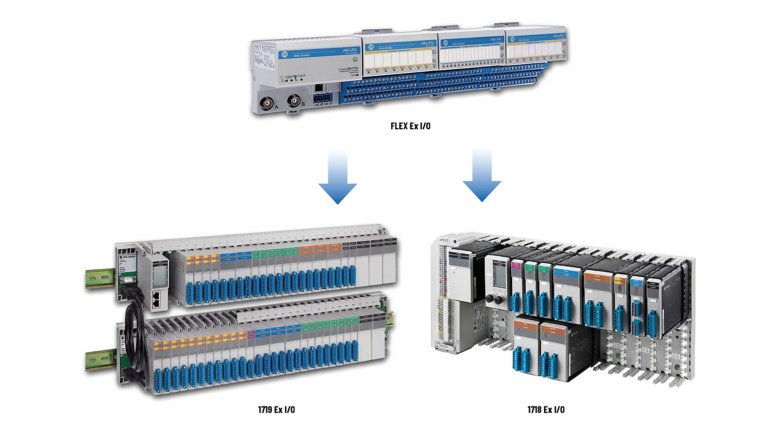

As the industrial manufacturing landscape evolves, so should your technology. Modernizing from legacy systems to newer technologies is not just an upgrade—it is a step toward more efficient, productive and safer operations. Start with FLEX Ex™ I/O to 1718 Ex I/O or 1719 Ex I/O modernization to maintain a competitive edge and meet the demands of smart manufacturing.

How can modernization maximize your competitive advantage?

Set up your operations for success

When your legacy system is using up more resources than it is supposed to, it can impact your overall manufacturing efficiency. With the discontinuance of FLEX Ex I/O, it is time to modernize your industrial automation architecture to the intrinsically safe 1718 Ex I/O or 1719 Ex I/O platform. Benefit from capabilities designed to optimize space and cost efficiency, improve operational resilience and ease device integration, even in hazardous areas.

Maximize uptime

Reduction in downtime with optional N+1 power supply redundancy and live maintenance using Removal and Insertion Under Power (RIUP)

Improve reliability

Safer operations and better protection of your assets in hazardous areas with the intrinsically safe I/O modules

Cut costs

Streamlined processes with simplified device integration, reduced wiring and decreased installation complexity

It’s time to unlock new possibilities

Ready to modernize your industrial operations? Our Modernization and Migration Services can help you evaluate your options for addressing legacy hardware. We have the engineering expertise to help assess, plan, and execute the best lifecycle strategy for your facility based on your business outcomes and needs. If you need support modernizing your FLEX Ex I/O architecture, we can help you:

- Modernize your legacy hardware to improve application functionality and increase security by leveraging capabilities of 1718 Ex I/O or 1719 Ex I/O platform

- Migrate your legacy hardware to mitigate your obsolescence risk by moving to the latest technology and reduce your maintenance costs and downtime

Why work with Rockwell Automation on your modernization or conversion project?

- Domain expertise and capability to help you develop a modernization path to address your biggest risks first and support desired business outcomes

- Utilization of local resources and long-term support with our global footprint

- Projects delivered based on your schedule, budget, and specific needs using Rockwell Automation best practices

Do it yourself

We offer many self-service migration resources for your aging systems:

- Easy-to-use hardware selection that can meet your application requirements

- User-friendly software tool to define and configure the 1718 Ex I/O and 1719 Ex I/O system automatically

- Customizable analysis and multi-site evaluation of your machines and equipment across your enterprise

Related resources and tools

Others also viewed

Based on your activity