It’s Time to Unlock New Value with Digital Innovation

In a fast-paced market, it can seem like customer demands change in the blink of an eye.

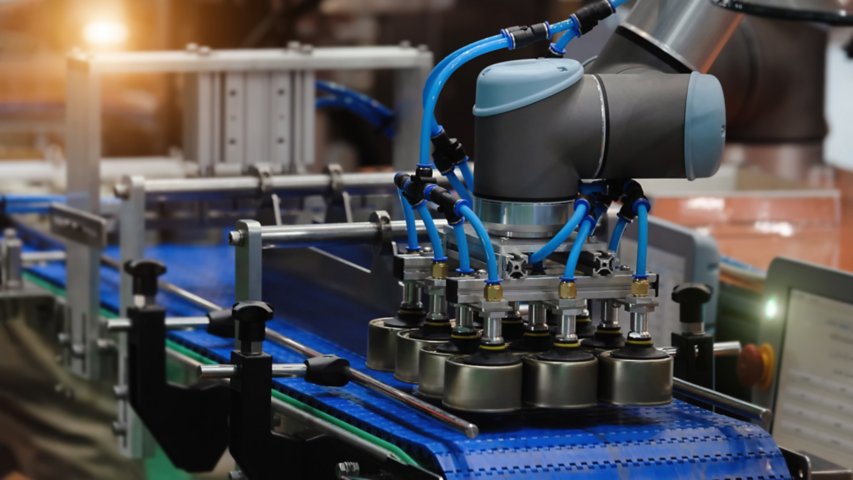

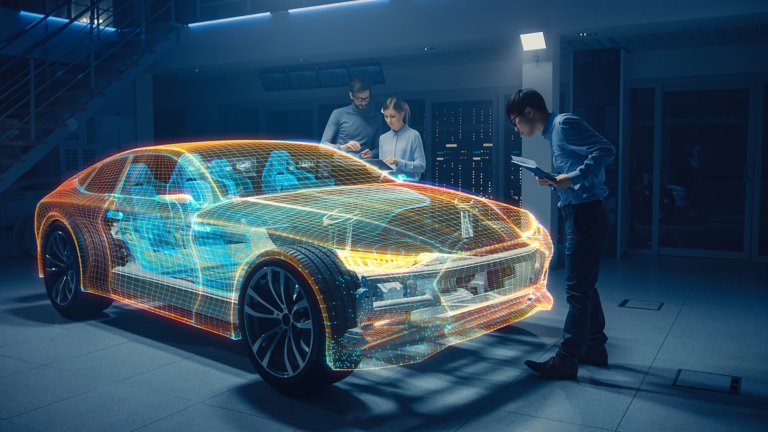

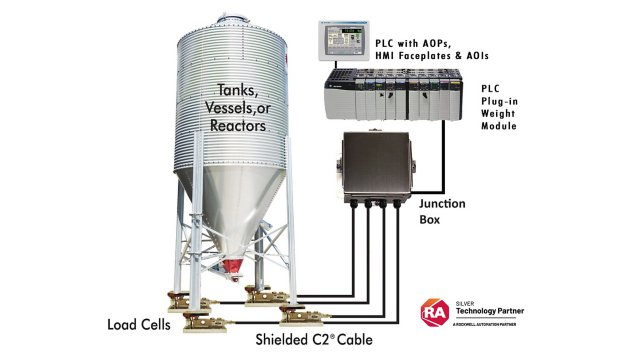

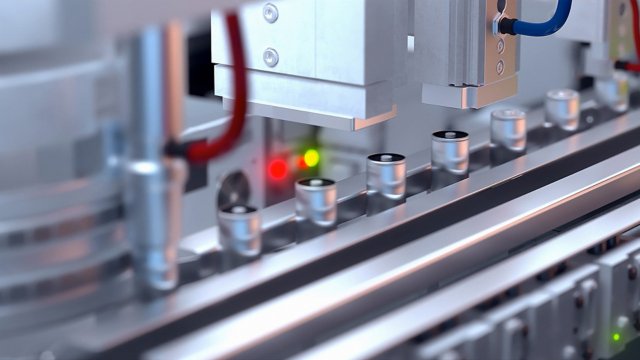

Now more than ever, end users are calling on their suppliers for more flexible, higher performing machines that deliver new levels of production value. With our digital solutions, OEMs can design and build machines with less risk and more efficiency. Your machines themselves can transform too. Our hardware and software enables the seamless flow of data so that you can make your smart machines more intelligent, scalable and dynamic.

Our digital solutions can help you:

- Improve efficiency in every phase of your development

- Innovate faster and deliver differentiated value

- Use data to enhance your solutions and unlock new business opportunities