In the Consumer Packaged Goods industry, the battle for shelf space is costly and fierce. Supermarkets and other retailers demand multiple payments for product placement including slotting fees for new offerings and hefty outlays for premium space sold by the inch.

Once shelf space is secured, manufacturers are motivated to get the most from their investment. And that means selecting cost-effective packaging methods that preserve the product, attract interest and conserve space.

A Better Choice

“Flexible pouch packaging is preferred for a wide range of products,” said Jeff Berg, product development manager, HMC Products. “The foil film laminates used for perishable items extend shelf life, and options like stand-up pouches display well and save space. Plus pouch packaging is a lightweight and more economical option overall.”

HMC Products has been meeting the needs of the market for over 40 years with its Pouchmaster line of horizontal form-fill-seal machines. Located in Machesney Park, Illinois, HMC serves a global customer base including Fortune 500 companies, co-packers and startups.

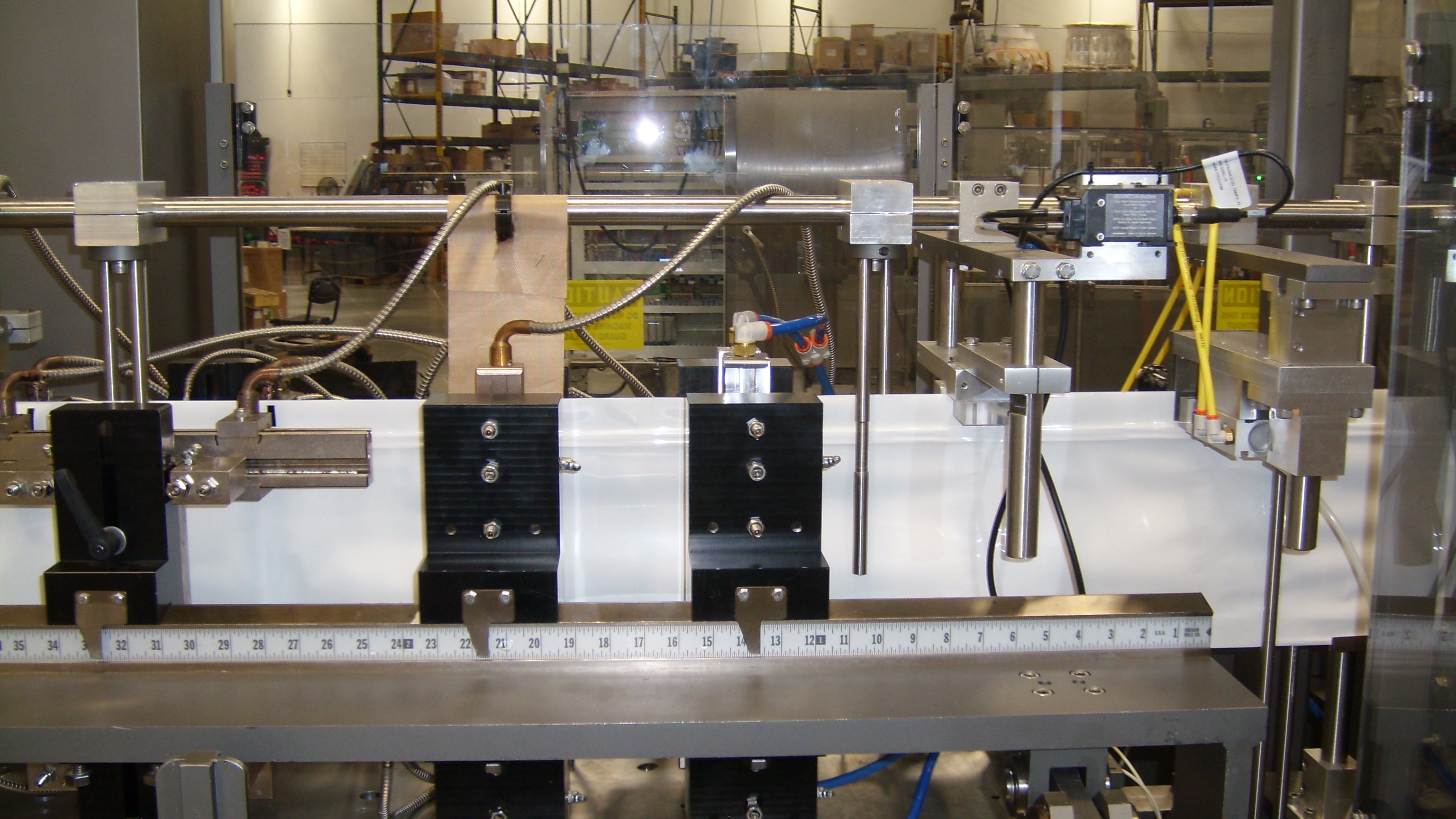

The IM 7-14 Pouchmaster is a highly efficient, intermittent motion machine featuring a quick change servo seal driver.

At the front end of the machine, film laminate is fed through a dancer bar, which controls film tension. Next, the film enters the forming plow and then proceeds through bottom and side seal bars located on top of the seal driver.

The film passes a registration photo eye that regulates the amount of film fed to a cutoff knife. The pouches are inserted in clips attached to a chain, and indexed through the filling stations. Finally, the pouches are sealed and offloaded via conveyor.

Optimize Pouch Fills

To achieve consistent seals, manufacturers must select pouch sizes that are large enough to accommodate quantities – and maintain sufficient headspace. The result is a pouch that is often underfilled.

Instead of heat, occasionally ultrasonic welding is used, which applies high-frequency acoustic vibrations and pressure to seal the top of the pouch. Stray product is fused as part of the seal – and does not affect seal quality. Therefore, pouches can be filled more fully.

Versatility in a Simpler Design

The flexible Pouchmaster can accommodate a full range of product feeders for solids, powders and liquids.

“This machine is not dedicated to one pouch size or product,” said Berg. “One customer runs seven pouch sizes on this machine – and another uses four different feeders.”

The HMC Pouchmaster is built on a Rockwell Automation® platform featuring an Allen-Bradley® CompactLogix™ controller. Allen-Bradley Kinetix® 5500 servo drives run the main machine shaft and the pouch transfer chain. Allen-Bradley PowerFlex® 525 AC drives control the conveyors. The machine is integrated on an EtherNet/IP™ network and monitored on Allen-Bradley PanelView™ Plus 7 graphic terminals.

“In addition, we recently simplified the design of the machine’s seal drivers by replacing cams and air cylinders with Kinetix servo control,” Berg explained. “As a result, the system requires less maintenance.”

Servo control also enables easy adjustment of the dwell time and opening and closing of the seal bars. The result is a better seal overall.

Smart Machine Performance

“The Rockwell Automation system makes the machine much smarter – and much easier to changeover,” said Berg. “To change a pouch size, the operator moves a few sealer bars and simply makes the appropriate selection on the recipe-driven HMI.”

Quick-change tooling expedites changeover for more significant product modifications.

“A smart machine can also tell you what’s wrong, with advanced diagnostics displayed on the interface,” Berg added.

To maximize uptime, HMC integrated a wide range of sensors into the control platform to quickly detect abnormalities – and incorporated visually intensive instructions in the HMI to guide maintenance. HMC also takes advantage of EtherNet/IP connectivity to service their customers’ equipment remotely.

“Downtime is money,” Berg said. “And all this technology is helping everyone – from plant managers to machine operators and maintenance personnel – keep equipment running optimally.”