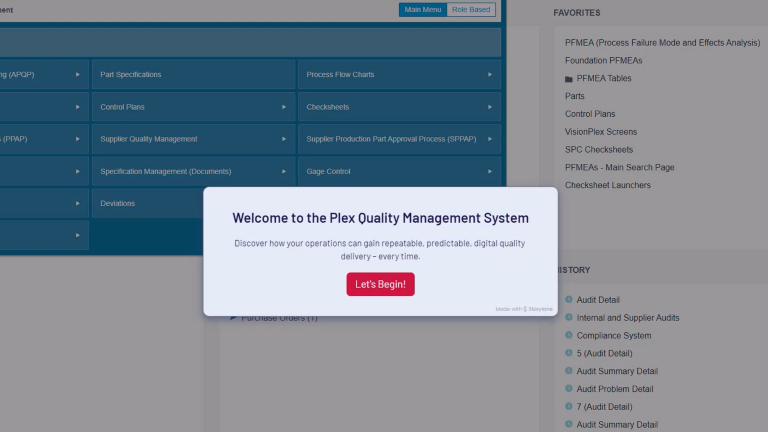

Obtain real-time quality control

Within the tire industry, new industry standards are increasing the need for manufacturers to reevaluate their operations and consider quality management systems (QMS). Quality management systems are essential for improving business operations and enabling you to meet industry regulations and customer-specific requirements. Several major automotive OEMs require QMS systems in their supply base to facilitate comprehensive quality control throughout the production lifecycle. Are you ready to stay compliant and get the most out of your system?

Plex QMS enables a single source of data that provides reliable, real-time data analytics which help manufacturers identify and address potential issues before they affect quality. Plex QMS also helps meet the International Automotive Task Force's IATF 16949 quality standard and best practices from the Automotive Industry Action Group (AIAG). Implementing Plex QMS will help empower tire manufacturers to optimize quality processes, minimize defects, and ensure consistent product quality.