Smarter, Greener Facilities

The ever-increasing output of data from global IoT and IIoT is driving demand not only for more data centers, but facilities that operate at maximum security and efficiency 24x7. This can be a significant challenge in any location, but it’s especially difficult when building data centers in remote areas where you have the necessary space but not the necessary access to reliable power and labor.

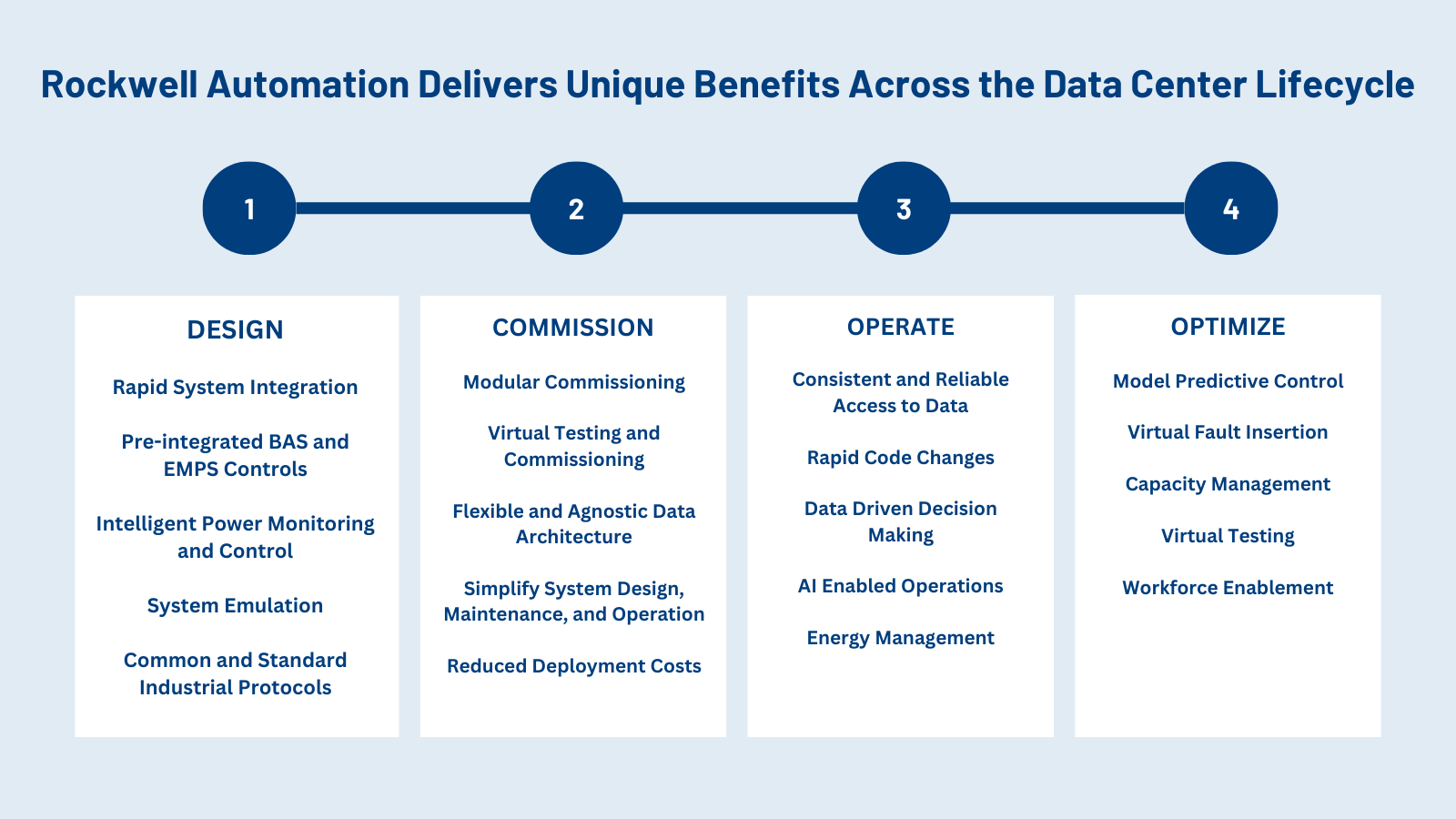

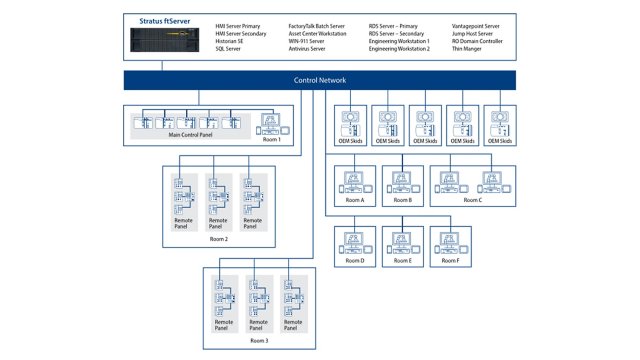

As the world’s largest company dedicated to industrial automation & digital transformation, Rockwell Automation understands the complex challenges, you face. Together with our proven PartnerNetwork™, we can offer you comprehensive solutions that help you create a data center facility that is not only more efficient, more resilient, and more sustainable, but helps you achieve the 99.999% uptime goal your customers demand.