You know the importance of building fast, flexible equipment for a wide base of customers. Your challenge is to balance your customer's need to maximize efficiency with their budgetary and time constraints. That’s where our hardware and software solutions can help.

Break Down Productivity Barriers using Emulation and Simulation

As a leading manufacturing and assembly machine builder, you’re constantly addressing new customer expectations while working to optimize your own operations. End users look to you for systems that not only improve cycle times but also reduce scrap and increase throughput. On top of that, your own engineering teams are always seeking new ways to be more productive and get projects up and running faster.

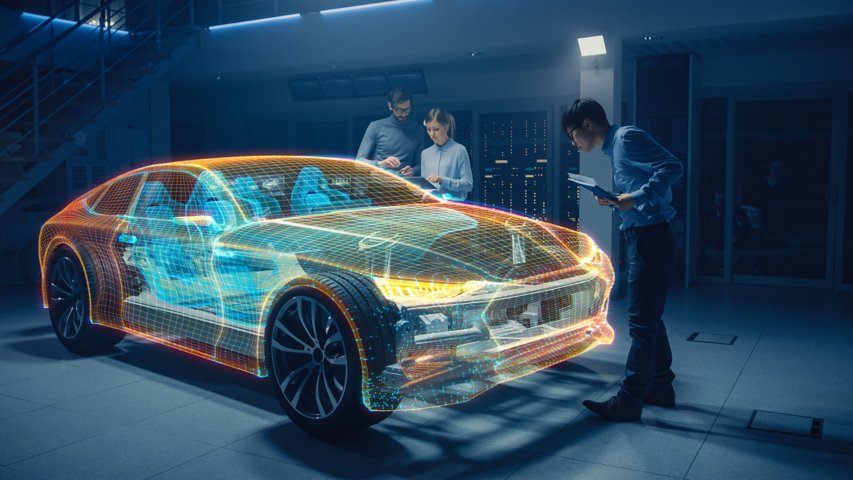

That’s where digital design comes in. Our solutions can help you create flexible equipment that responds to dynamic production needs, while boosting design and engineering productivity for your own teams.

Capabilities like digital emulation and simulation enable testing and iteration in a virtual environment, where design pivots are much less costly. You can see what control and configuration changes are needed to optimize OEE before physically implementing in the real world. Plus, you can prove out that the total solution meets the end-user specs prior to build, which reduces risk and leads to more wins for everyone.

- Improve customer satisfaction by collaborating with potential customers during the quotation phase

- Reduce design time and costs by shifting important controls programming tasks earlier in the project

- Increase commissioning efficiency by diagnosing and fixing issues earlier and eliminating redundant checks such as IO checkout

- Test and validate different production scenarios of online systems before going live

- Train teams more efficiently by testing on any scenario using a virtual environment

How are Manufacturing & Assembly OEMs Focused on the Future?

Digital-first optimization

Work smarter in a virtual environment and design machines that harness the power of data

Flexibility and modularity

Deliver systems that efficiently scales to dynamic production demands

Smart, sustainable machines

Use data to optimize processes and advance sustainability efforts

Sharpen Your Competitive Edge

See how our hardware and software technologies can help you drive innovation in your processes, adapt to new customer demands, improve your solution offerings and deliver differentiated value.

See our Manufacturing & Assembly Solutions in Action

Leading Manufacturing & Assembly OEMs are Redefining Machine Performance

The most innovative manufacturing and assembly machine builders trust Rockwell Automation technology to deliver results and help them succeed. Explore how our solutions can help you design smarter, optimize processes, facilitate innovation and drive profitability.

Explore What’s Next in the Industries You Serve

Others also viewed

Based on your activity