As energy costs continue to increase globally, driven by the depletion of fossil fuels, geopolitical instability and disruptions in the global supply chain, manufacturers strive to achieve energy efficiency, reduce overhead and minimize the total cost of operations. Improved awareness of energy usage is the foundation for any strategic energy management program.

Pressure points driving new focus on energy

Energy demand

Digitalization & electrification

Energy efficiency

Energy costs

Climate changes, net-zero commitments

Regulations

As energy costs continue to increase globally it helps an organization understand where, when and how it uses energy to establish the necessary scope of its energy savings efforts and define key metrics.

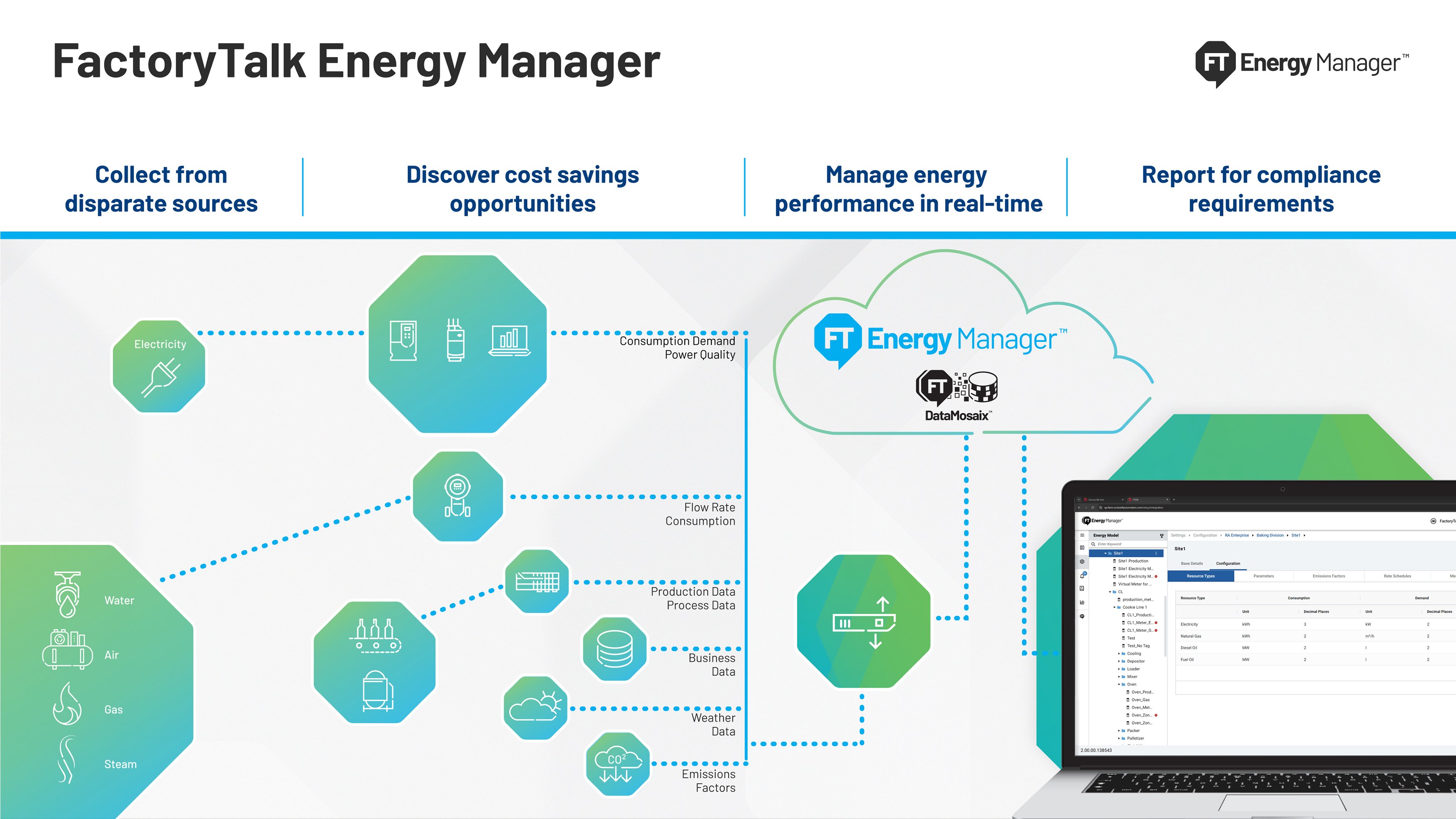

FactoryTalk Energy Manager

Understand and optimize energy usage with contextualized analytics. Monitor, analyze and optimize energy performance.

Introducing FactoryTalk® Energy Manager™, an IT/OT convergence platform-based energy monitoring application that provides energy and production information based on an energy plant model of the underlying process at a plant, process area, line and machine level. Manufacturers can understand where, when and how their facilities use energy to establish the necessary scope of their energy savings efforts and define key metrics.

Aggregate and contextualize energy data

Monitor, analyze and compare energy performance

Prebuilt real-time energy performance dashboards

Reporting and notification management

Make informed decisions based on your energy consumption

Built on an Industrial DataOps platform

FactoryTalk Energy Manager is built on FactoryTalk® DataMosaix™. Built for multi-site, enterprise-wide access, FactoryTalk DataMosaix enables controlled access to relevant and contextualized data. It’s an Industrial DataOps solution that provides flexible and scalable tools to accelerate data usability by domain experts and analysts.

Application Benefits

Optimize Production

Clear dashboards highlight areas for improvement and optimization

Reduce Consumption

Per utility information is trended to help users identify opportunities for energy reduction

Reach Goals

Standard IT/OT platform enables faster return on investment and accelerates your digital transformation

Energy management can deliver untapped savings for your enterprise

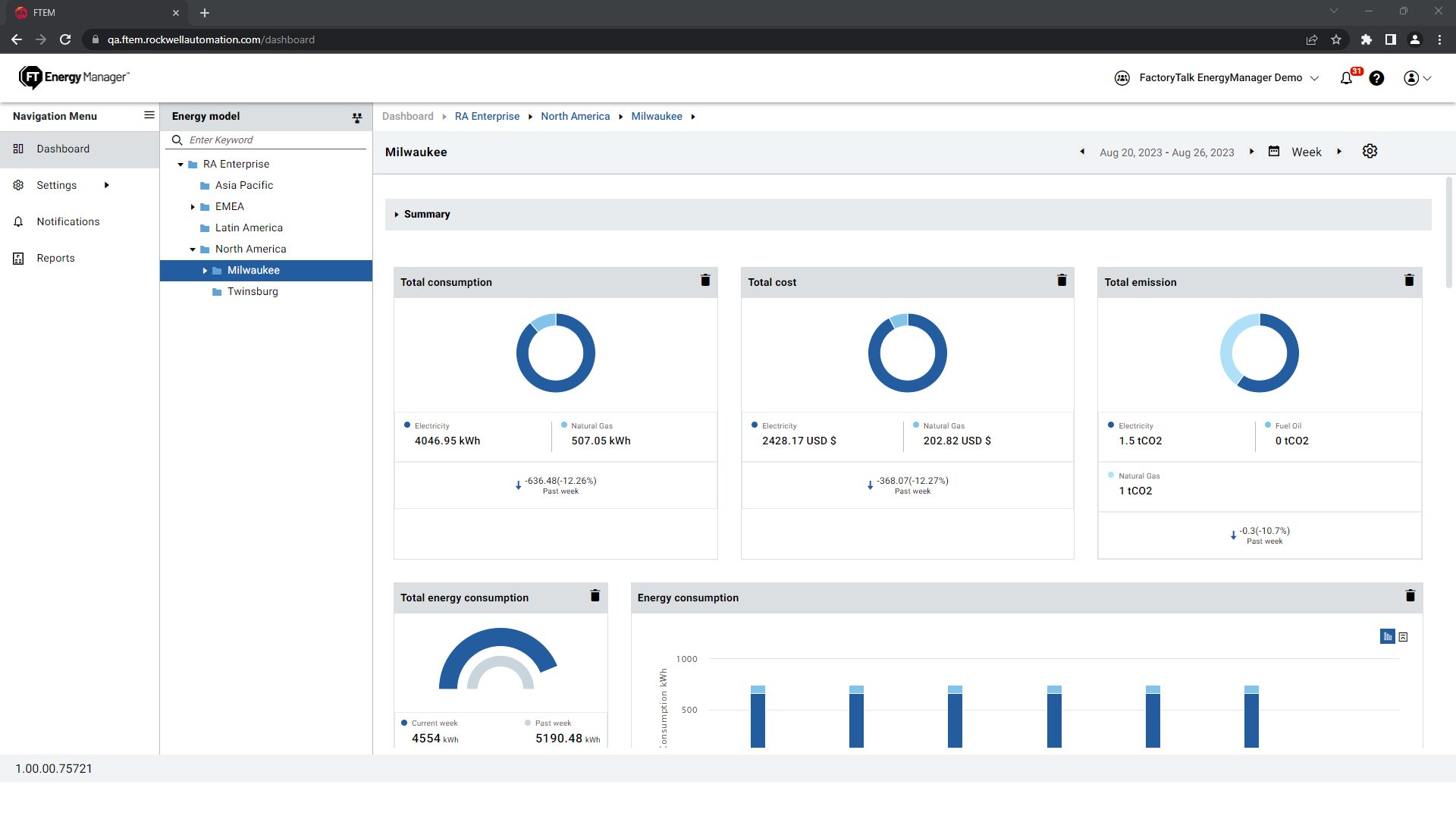

Boost Visibility at Every Level

Reporting for site, area, line and machine

Report Examples

- Total energy use, consumption trends

- Daily plant usage detail, totals and averages by area and energy type

- Weekly comparison, area and time selectable

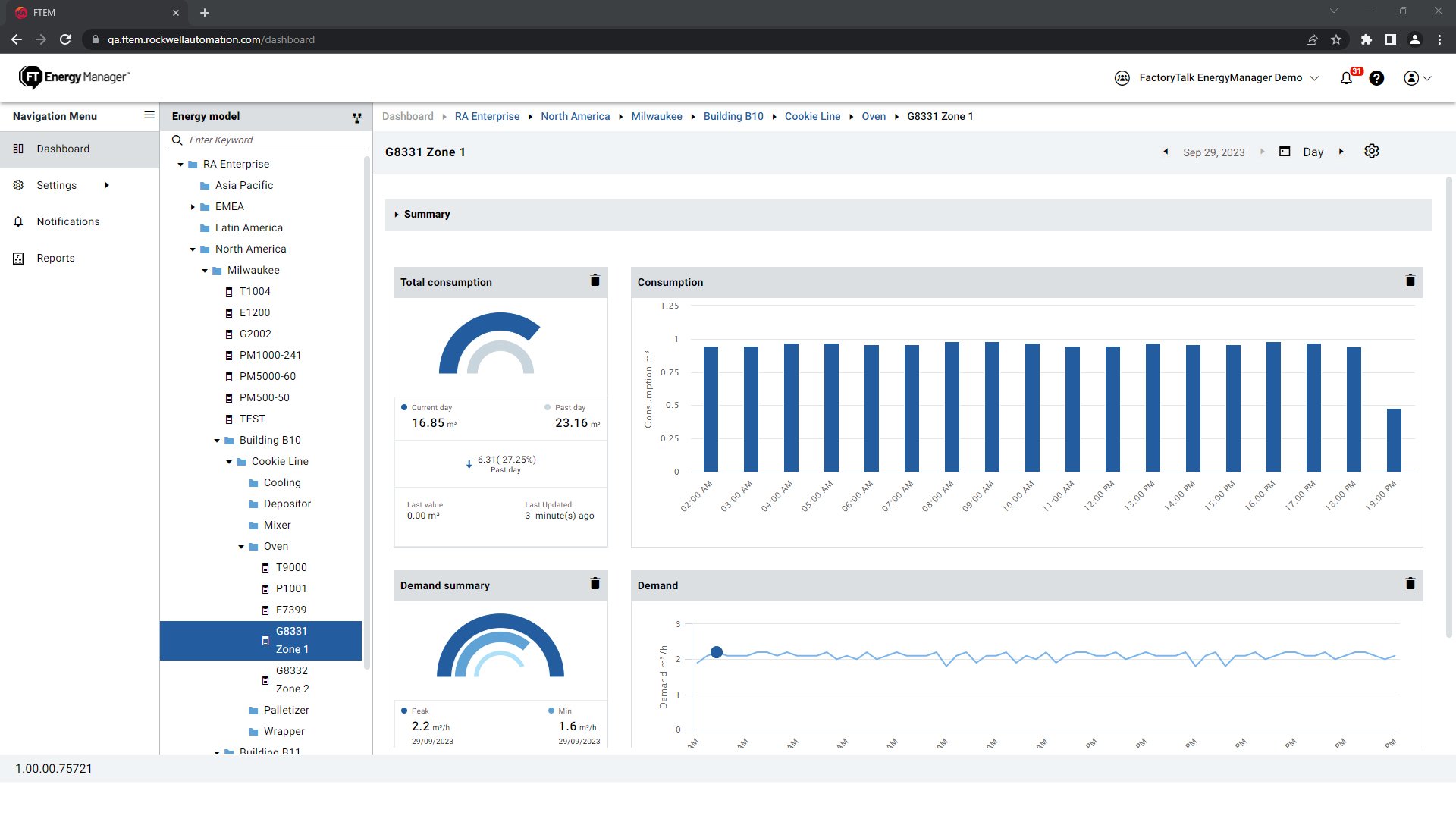

Dashboard Examples

- Trends for water, air, gas, steam, electric (WAGES)

- Consumption, intensity and production data

- Trends based on plant model (site, area, line, machine)

- Customized time frame

Collaboration and Support

Services to help you achieve your sustainability goals

Profiling and Analysis

- Energy opportunity analysis, business case

- Energy management infrastructure and data review

Planning

- Energy management requirements and solution design

- Energy optimization transition plan and budget

- Energy management program structuring and program management

Implementation

- Proof of value pilots

- Scale multi-site implementations

- User adoption and change management

- Managed services and outsourcing

Why Energy Monitoring Applications Matter

Our strategy is based on environmental, social and corporate governance (ESG) standards and remains focused on driving three outcomes for manufacturers: sustainable customers, sustainable companies and sustainable communities. Energy management systems are integral to our country's transition to widespread electrification and decarbonization. The Factory Talk Energy Manager industry solution will help customers to connect data (energy, water and production data) from different data sources and provide them the appropriate functionalities to monitor and analyze on consumption, demand, intensity, costs and emissions. The system will help to compare assets, gain insights on savings and baseload as well as provide a forecast on important KPI´s. Furthermore, customers can contextualize energy data with production data, execute intelligent energy assessments and run data or asset correlations to identify inefficiencies or anomalies.

Scalable Solutions

Innovations to improve operational insight across your business

Ready to Order Your Software?

Recommended for You

You may also be interested in