Competitive market demands require higher yields, superior quality and greater throughput. This can lead to increasingly complicated assembly systems, higher compliance costs and strain on overloaded systems. We offer integrated automation and information solution to address your medical manufacturing needs.

Improve Quality, Compliance and Time to Market

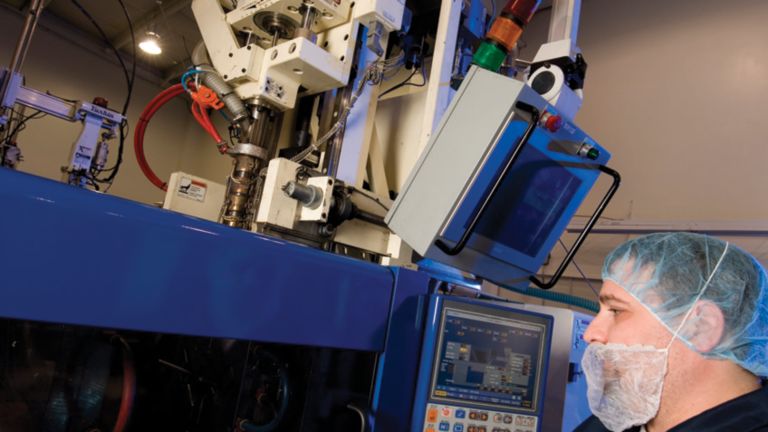

Medical device manufacturing companies are driven by immense pressures to help ensure safety, accuracy and regulatory compliance throughout the production process. These manufacturers increasingly turning to automation to improve their competitive position.

We provide a fully integrated automation and information solution for medical device manufacturers. We help them reduce the amount of manual labor, which leads to increased throughput, improved quality and lower costs. Key benefits include:

- Improved efficiency with integrated systems

- Increased visibility which allows for full traceability

- Reduced cost of compliance

- Reduced cycle times

More flexible and agile medical manufacturing systems are needed to meet standards and address the growing importance of manufacturing intelligence. We can help get you there.

Drive Excellence Across the Enterprise

Efficiency in the medical device manufacturing process is a crucial factor to reduce overall time to market. Solutions to help eliminate paperwork, reduce errors and maintain high-quality standards will increase the throughput of the plant. At the same time, it will help eliminate resources that are performing unnecessary tasks and help reduce material waste.

Our PharmaSuite® manufacturing execution system (MES) provides seamless integration from ERP to shop floor, real-time quality dashboards and more. Based on S88 and S95 standards, PharmaSuite software includes order-management and electronic device history record (eDHR) support to help ensure the assembly process for every medical device is tracked and documented. Rework and repair capabilities also help streamline tasks for any devices requiring such work.

Advanced Scientifics Gains Manufacturing Intelligence

Advanced Scientifics Inc. (ASI), a leading global producer of single-use systems for biotech, wanted to improve its data collection and reporting capabilities on several medical instrument production processes. By implementing our medical manufacturing intelligence solutions, they:

- Improved customer experience

- Reduced downtime due to new reporting methods

- Improved their competitive status

Improved Productivity and Quality

In response to the growing demographic of baby boomers, a leading medical device manufacturer had a need to expand production capacity. Using a manufacturing intelligence strategy that included our FactoryTalk® software suite, this company:

- Increased its productivity 20% over previous systems

- Established paperless reporting

- Implemented end-to-end track and trace systems to improve quality control

Flexible and Scalable Solutions for Packaging

Our iTRAK® Intelligent Track System is a modular, scalable linear motor system that allows for independent control of multiple movers on straight or curvilinear paths. iTRAK replaces hardware with simple, effective software profiles that redefine speed and flexibility in automation, making it possible for you to:

- Increase production rates 50% or more

- Reduce downtime for changeovers

- Reduce periodic maintenance

Optimized Performance, Productivity and Profitability

Competitive market demands require higher yields, superior quality and greater throughput. We offer a comprehensive portfolio of solutions to address medical device manufacturing needs. We can help you improve quality and compliance, increase yields, improve time-to-volume, and automate your complex processes.

Related Products and Solutions

Others also viewed

Based on your activity