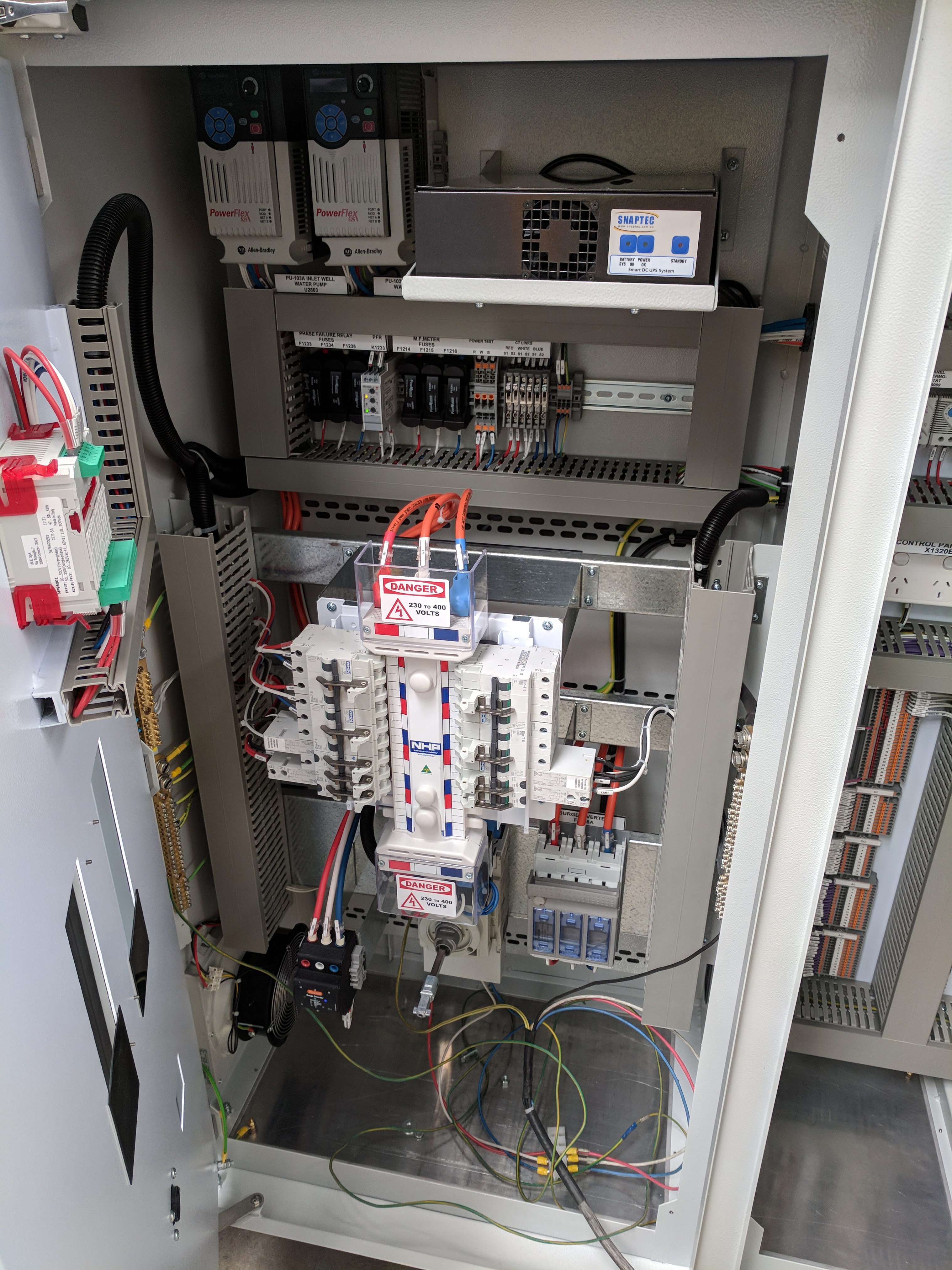

PowerFlex 525 drives with Safe Torque-Off provided integrated motor control and safety.

Challenge

- To design, build and commission a pilot plant to produce syngas and monitor the technical and environmental performance of the process

Solutions

- PlantPAx® Distributed Control System - Delivered advanced plant-wide control and optimisation for the plant

- Allen-Bradley® CompactLogix™ controllers - Optimised productivity and reduced commissioning

- PowerFlex® 525 drives with Safe Torque-Off - Provided integrated motor control and safety

- FactoryTalk® View SE - Delivers insight and visibility into the system

- FactoryTalk VantagePoint - Provided remote access to production data, analysed trends and environmental reporting; FactoryTalk Historian was used to capture critical data and provide this for detailed analysis

Results

- High availability - System operated 24/day, 7 days/week with no downtime issues

- Successful syngas production - The pilot project resulted in successful production of syngas – with a peak flow rate of 7.5mmcf/day

- Leigh Creek Energy has operated the ISG gasifier safely within established environmental parameters

The Leigh Creek Energy Project is an in situ gasification converting coal from its solid state into its gaseous form.

Leigh Creek Energy Limited is an innovative energy company focused on developing its Leigh Creek Energy Project (LCEP), located 550km north of Adelaide, South Australia.

The company’s flagship project is the Leigh Creek Energy Project – an in situ gasification (ISG) converting coal from its solid state into its gaseous form. This process results in the generation of synthetic natural gas (syngas) containing methane, hydrogen and other valuable components. The syngas can be either used to produce electricity directly or further refined into a variety of products including synthetic methane and ammonia.

To obtain information to inform the design for a potential commercial facility, Leigh Creek Energy established an ISG demonstration facility. This involved the construction of an above ground plant and the establishment of a below ground single ISG gasifier chamber.

The Leigh Creek Coalfield was selected as an appropriate site for the pilot facility as a result of a screening process using criteria that covered environmental, technical and commercial aspects for ISG. These findings confirmed that the site was suitable for undertaking ISG processing in a manner that was safe and minimised environmental impact.

The pilot plant was commissioned and operated reliably for the 90 day trial period to produce syngas, allowing for the technical and environmental performance of the process to be analysed.

Delving into the plant

The challenge at hand was to design the ISG process and keep the pilot plant running continuously without any stoppages. ATSys, a Rockwell Automation Recognised System Integrator, was commissioned to develop the electrical implementation and control system for the plant.

The ISG process is a chemical conversion from solid coal to gas. For the reactions to commence, air is introduced through the inlet well, and an initiation device is used to create very high temperatures. As the temperature and oxygen concentration reach optimum levels, a series of reactions convert the solid fuel into syngas, which is then extracted through the outlet well.

The area in the coal seam where the gasification takes place is referred to as the gasifier chamber; the reactions that form syngas typically occur at temperatures of between 900°C and 1200°C. Given the process, safety and environmental considerations for the plant, the choice of control and automation system requirements was of paramount importance.

“We selected Rockwell Automation hardware and software for this project because it has been proven to be reliable, and we could be confident that the technology would be fit for the purpose of this project,” said Andre Tassone, managing director, ATSys.

Plant-wide control, mobility and visibility

The Rockwell Automation PlantPAx® distributed control system delivered advanced plant-wide control and optimisation for the plant. By using a common automation platform, the PlantPAx system provided seamless integration between critical process areas of the plant. In addition, the Allen-Bradley® CompactLogix™ controllers together with PowerFlex® drives with Safe Torque-Off delivered a fully integrated architecture. The Integrated Architecture® solution allowed all equipment to seamlessly integrate over Ethernet into the controllers, allowing fast, reliable control with detailed diagnostics for this critical application.

Reducing engineering time associated with installation and commissioning was a key priority for the project. The PlantPAx Library of Process objects is a pre-defined library of controller code (Add-On Instructions), display elements (global objects), and faceplates that let you quickly assemble applications with proven strategies, rich functionality and known performance.

“By using the PlantPAx Library of Process Objects in the Leigh Creek project, we were able to reduce the engineering and testing time involved. We also decided to design all the equipment on skids to reduce installation time on site,” explained Phil Galbraith, principal control systems engineer, ATSys.

The FactoryTalk product suite provided real time visibility into the system for monitoring and controlling the plant.

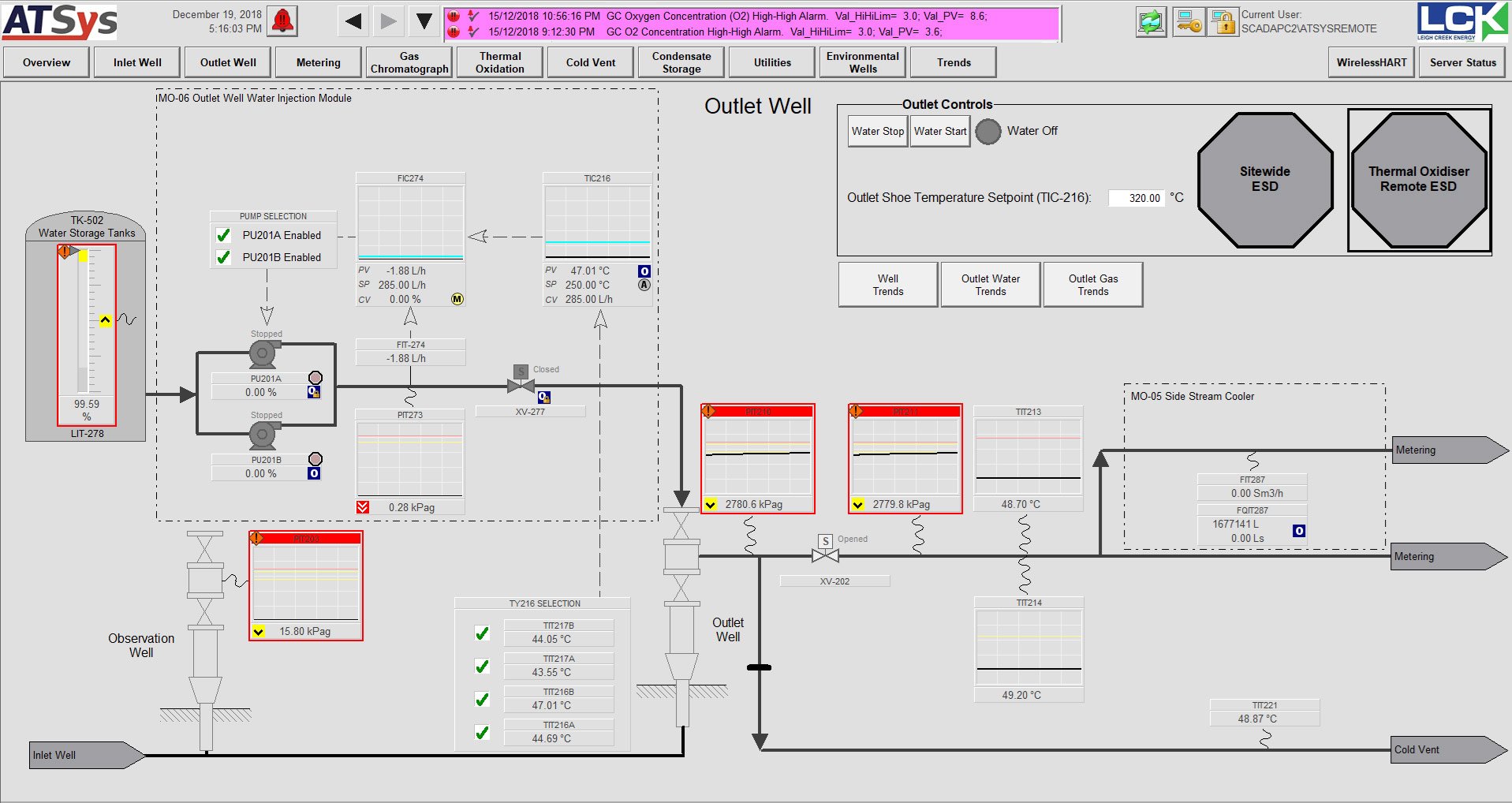

The FactoryTalk® product suite provided real time visibility into the system for monitoring and controlling the plant. FactoryTalk View SE was used in a redundant configuration for visualisation and control on a pair of PCs running in the control room onsite, helping to ensure reliability for critical control and monitoring functions. FactoryTalk Historian SE and FactoryTalk VantagePoint were used for logging of historical data and visualization on a cloud-hosted system.

As the pilot plant was in operation 24 hours a day, seven days a week, it was important for operators to be able to access data remotely. This platform also enabled the capability for remote access to the production data. In addition to having access to real time data, it was critical to log data for analytics and reporting analyse trends, investigate inefficiencies and monitor environmental KPIs.

CompactLogix controllers optimised productivity and reduced commissioning.

Successful syngas production

As with all pilot projects, there is always a risk that the project may not be commercially feasible. This was not the case with the Leigh Creek Energy Project; in fact, its success exceeded expectations. The pilot project resulted in the successful production of commercial syngas – with a peak flow rate of 7.5mmcf/day which was higher than anticipated for the ISG process. In addition, the pilot study demonstrated that Leigh Creek Energy has operated the ISG gasifier safely through data analysed from surrounding environmental monitoring wells before, during and after the trial.

The data recorded reveals that the size of the gas resource is significant, making this resource one of the largest undeveloped, uncontracted and undervalued gas resources within the East Coast gas system in Australia. Unlocking the value of such a significant energy resource will provide Leigh Creek Energy with the foundation to progress the project to the next commercial stages.

“The success of this trial has effectively unlocked a large energy resource of huge value and captured key data that validates the fact that this proven ISG technology can be successful in a commercial application,” said Phil Staveley, managing director, Leigh Creek Energy.

Published July 8, 2019

Recommended For You