With the large upfront costs often involved in new plant automation solutions, problem-solving engineering company, Products For Industry (PFi), based in Queensland, Australia, has found a way to provide its customers with additional certainty, and reduced risk.

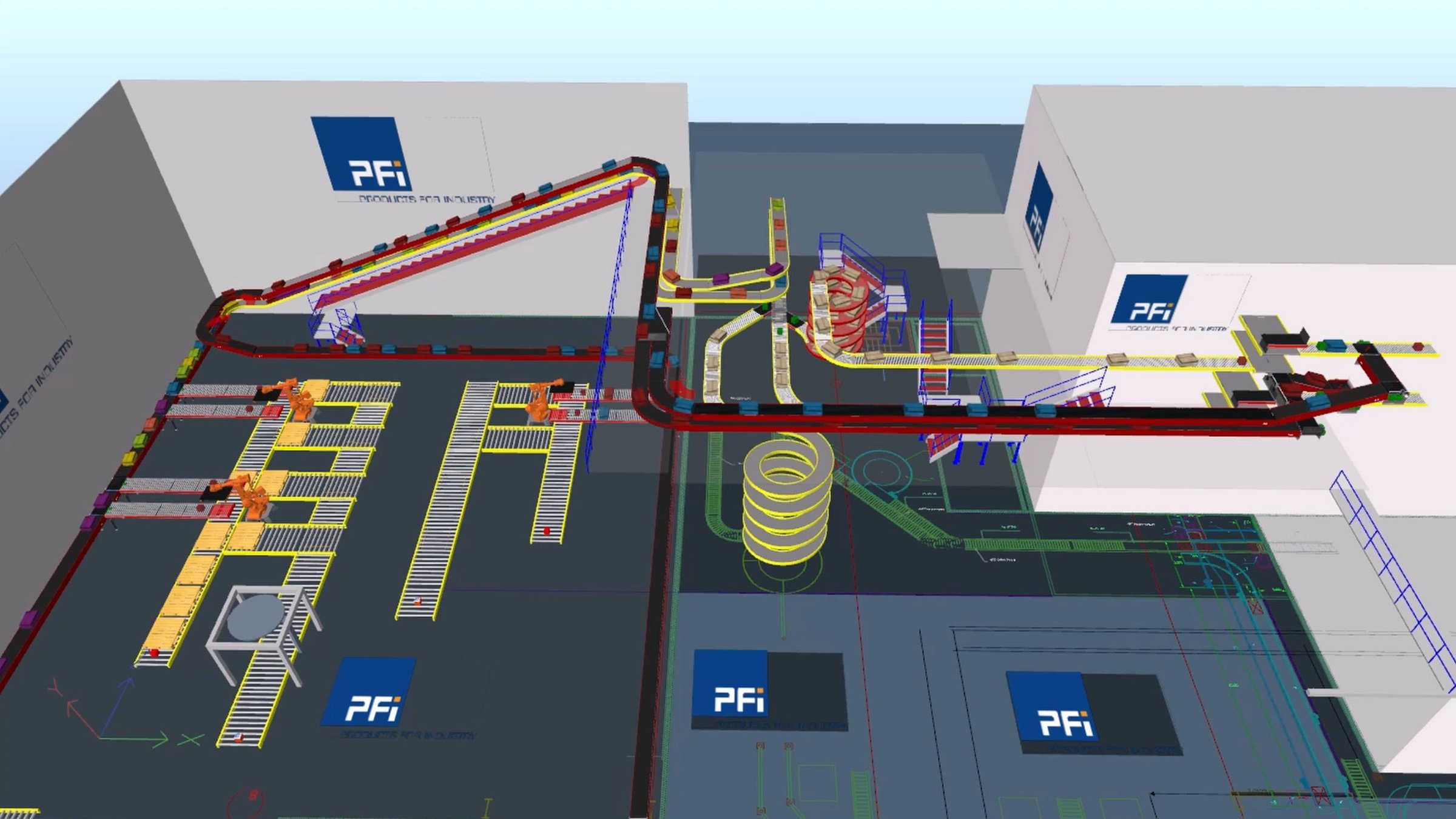

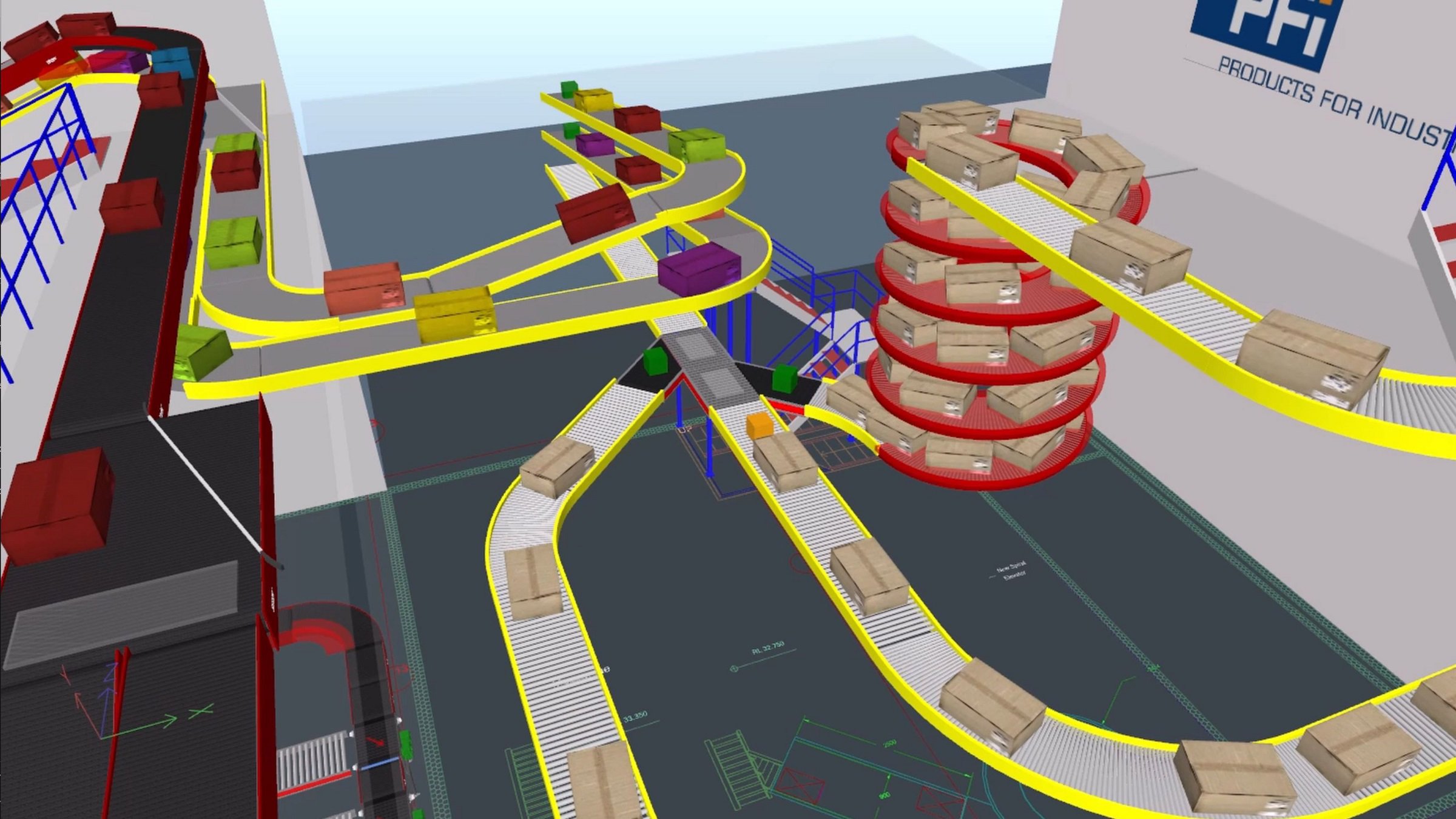

PFi employs Emulate3D™ by Rockwell Automation to create a digital twin, and completely visualise a new or upgraded plant, prior to the physical implementation.

Using 3D CAD modelling and integrated automation software, Emulate3D allows users to test the entire production process virtually, which helps to optimise the solution to save customers space, time, downtime, energy usage, and cost.

Gavin Dunwoodie, managing director, PFi, said, “More and more customers are asking for a simulation during the tender process, so if we can show exactly how well our solution will work, the ROI they are likely to achieve, and that we are meeting industry best practices, it gives us a real competitive advantage. We use Emulate3D software during the tender process to visualise customer operations using our machinery as part of our pitch.”

“Since incorporating Emulate3D into the process, we have seen a greater win rate, as customers can see the product working before they purchase. Yes, there are upfront costs, but they pay dividends as the customer is willing to pay a premium to see that the product produces needed, and often increased results,” added Dunwoodie.

PFi is a locally owned and operated business servicing the industrial sector. The company offers a full suite of in-house capabilities to support manufacturers with machine automation products, systems and solutions.

For brand new plants or automation retrofits, PFi uses Emulate3D by Rockwell Automation to showcase exactly how the new plant will run, down to the finest details.