Transform what’s Possible in Design with Digital Twin Software

Changing demands in a fast-paced workplace has demonstrated the need for a more agile design process.

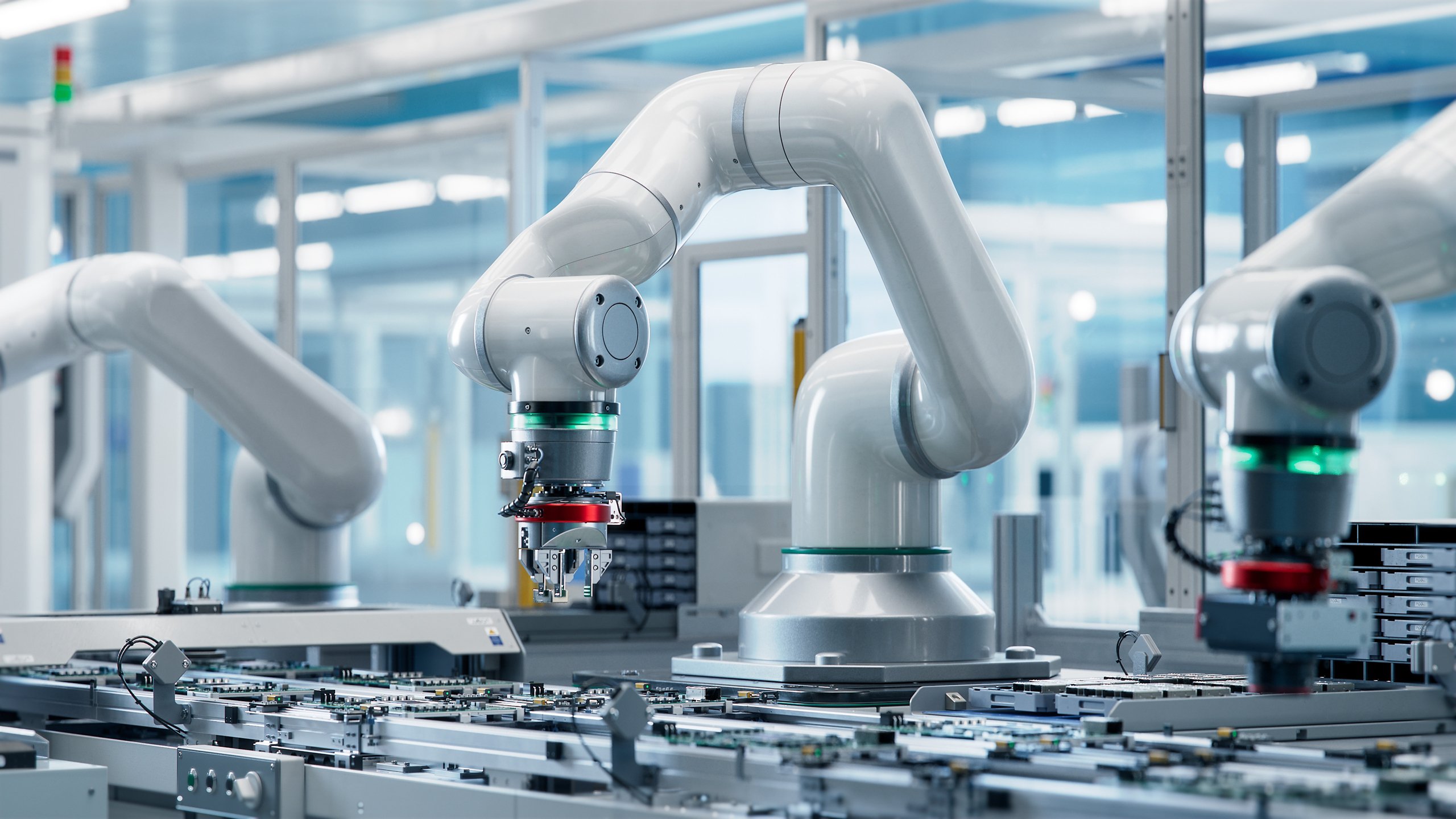

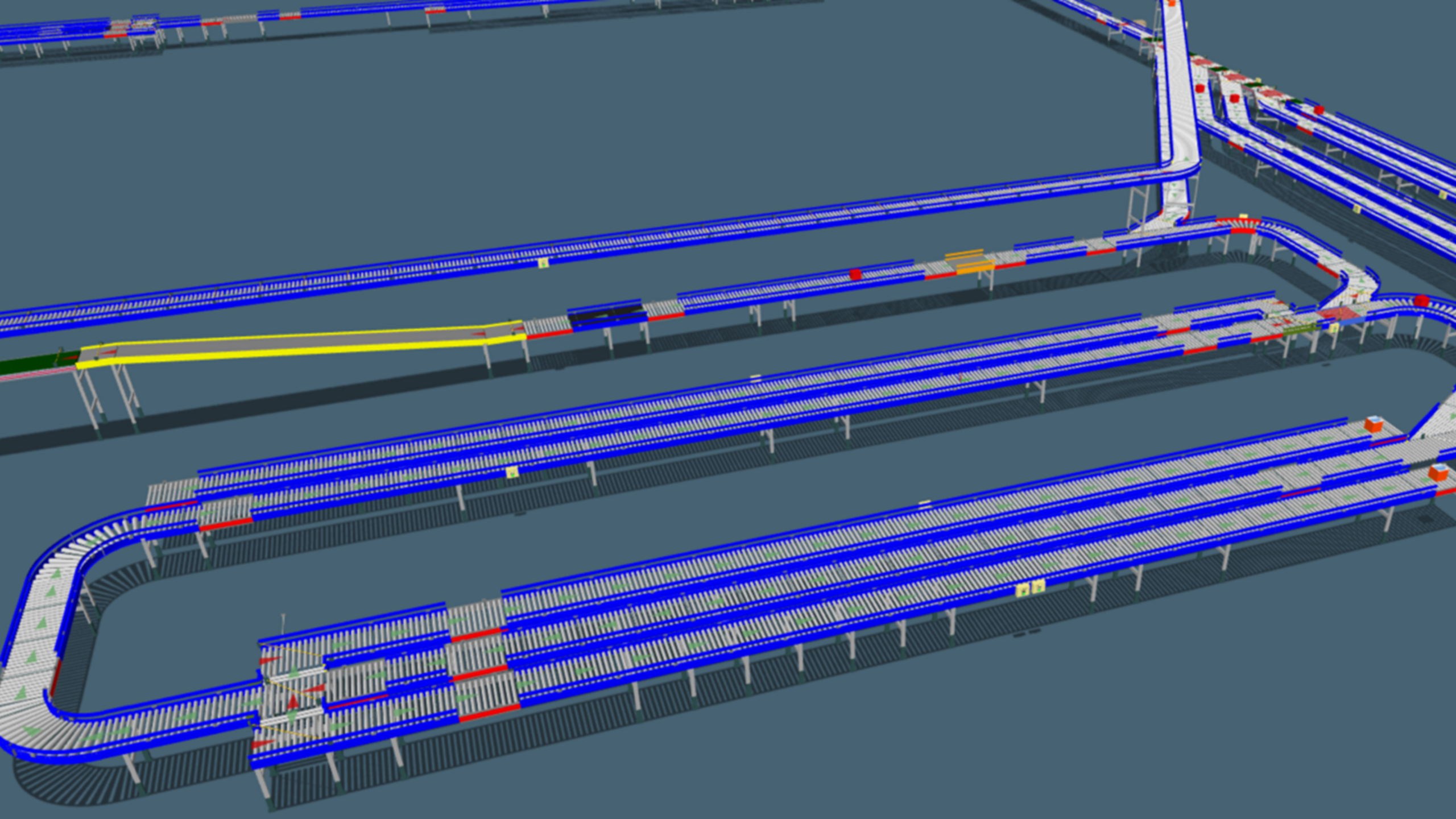

End users are seeking ways to test new designs of their automated systems, offline and earlier in the project lifecycle, to reduce risks and potential rework. With Emulate3D™ digital twin software, users can identify potential control issues preemptively, saving valuable time and resources during implementation. Plant personnel receive additional support by having a virtual space to train on new systems, predict future performance, and simulate line changes without real-world consequences. Emulate3D digital twin software provides a comprehensive and dynamic approach to enhancing efficiency and precision in industrial operations.

Our digital twin software can help you:

- Reimagine the design process by using virtual design and prototyping

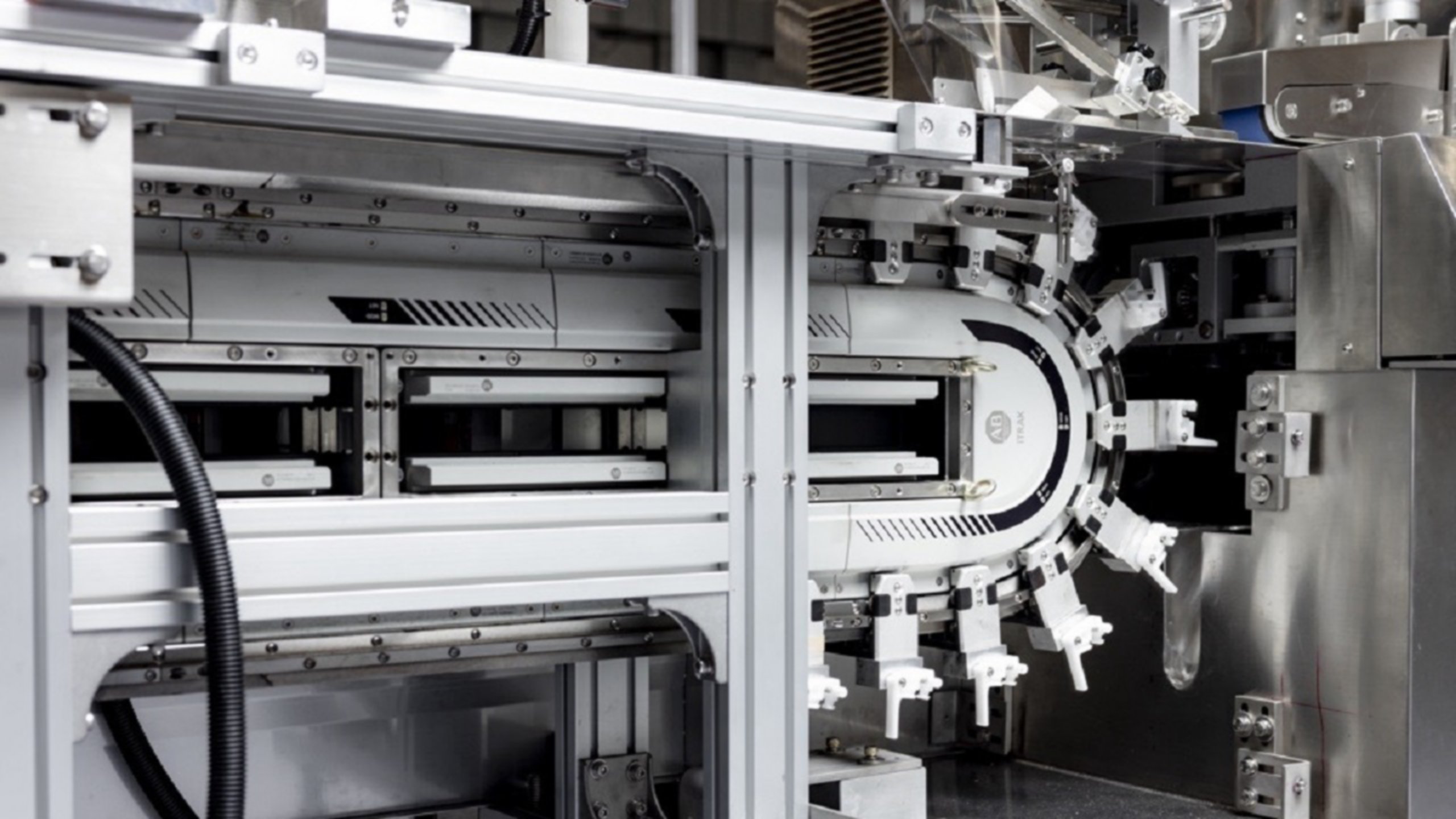

- Establish early connections between your machinery and control systems, helping to resolve operational and sequencing issues before on-site deployment

- Improve production by employing faster-than-realtime 3D simulation to help you identify optimal design layouts and configurations