Warehousing and Logistics Automation Software and Hardware Solutions

Keep operations moving amid skills shortages and handle a wider range of goods than ever before with automated warehouse systems

Advanced warehouse automation and information solutions continue to transform the way we approach warehousing, supply chain and logistics. From forecasting and inventory replenishment, to visibility and end-to-end traceability, today’s smart systems are designed to improve and accelerate the way companies move goods.

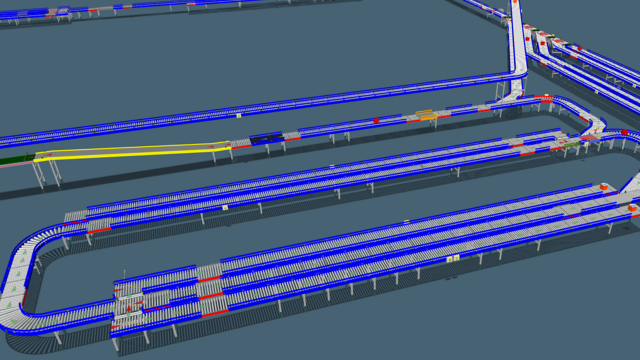

The efficiency and reliability of material handling systems often determine the productivity and profitability of a warehouse and fulfillment center. We can work with you to design and deliver automated warehouse and logistics solutions with the future, and today, in mind.

Traditional material handling can’t keep up

- Many systems are not designed to handle today’s consumer demand

- New packaging sizes and shapes create bottlenecks in sortation and inefficiencies in gapping and singulation

- Fixed systems create limitations for expandability and reconfiguration of workflow

- Required modifications to traditional systems can create cost and operational risk