Drive Simplification

Rockwell simplifies highly complex industrial challenges through automation and digital solutions, so our customers can find more ways to win

We meet customers where they are in their journey with our hardware, software and services that harness the potential for every business. Our goal is to drive simplification through our industry-focused solutions and our powerful partner ecosystem.

Drive Simplification

Rockwell simplifies highly complex industrial challenges through automation and digital solutions, so our customers can find more ways to win

Industry Focus

Rockwell is the largest pure-play automation company with market leading technologies in discrete, hybrid, and process industries

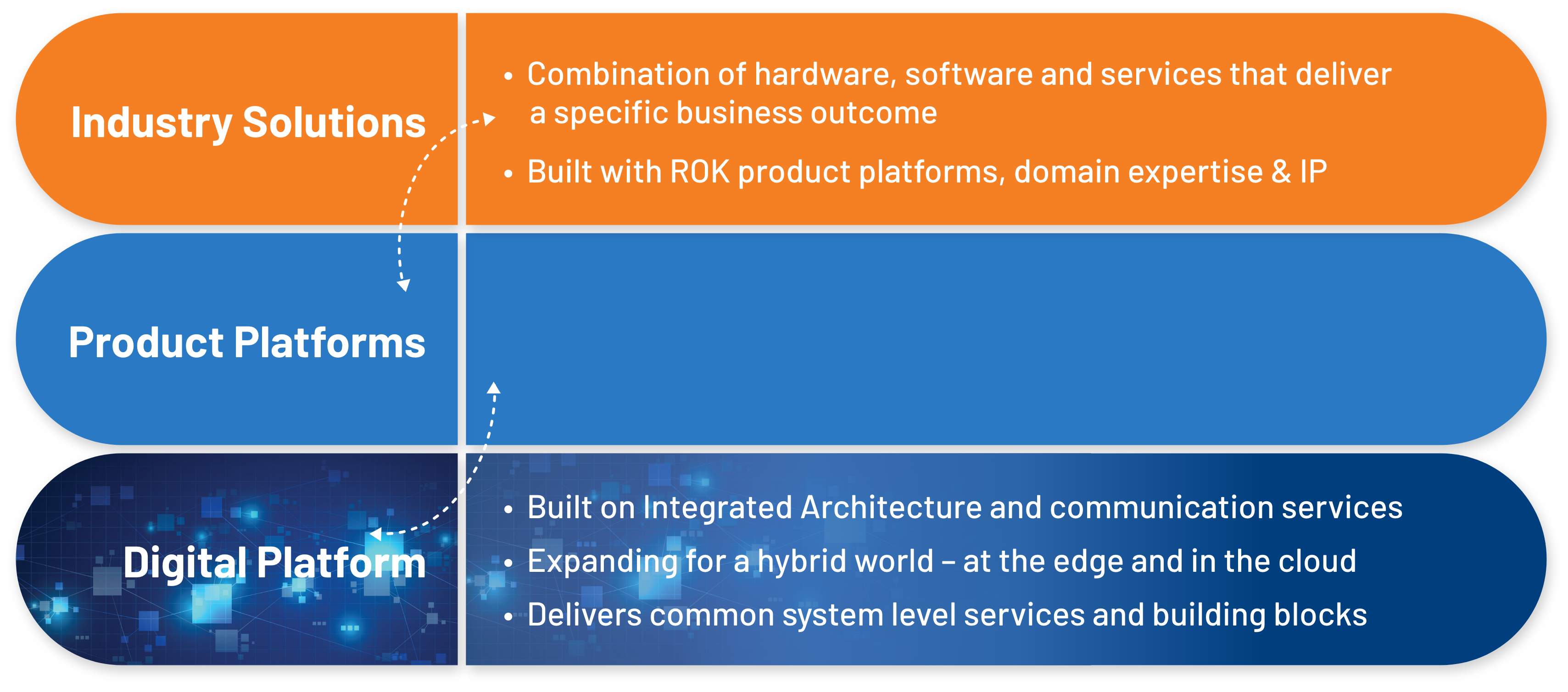

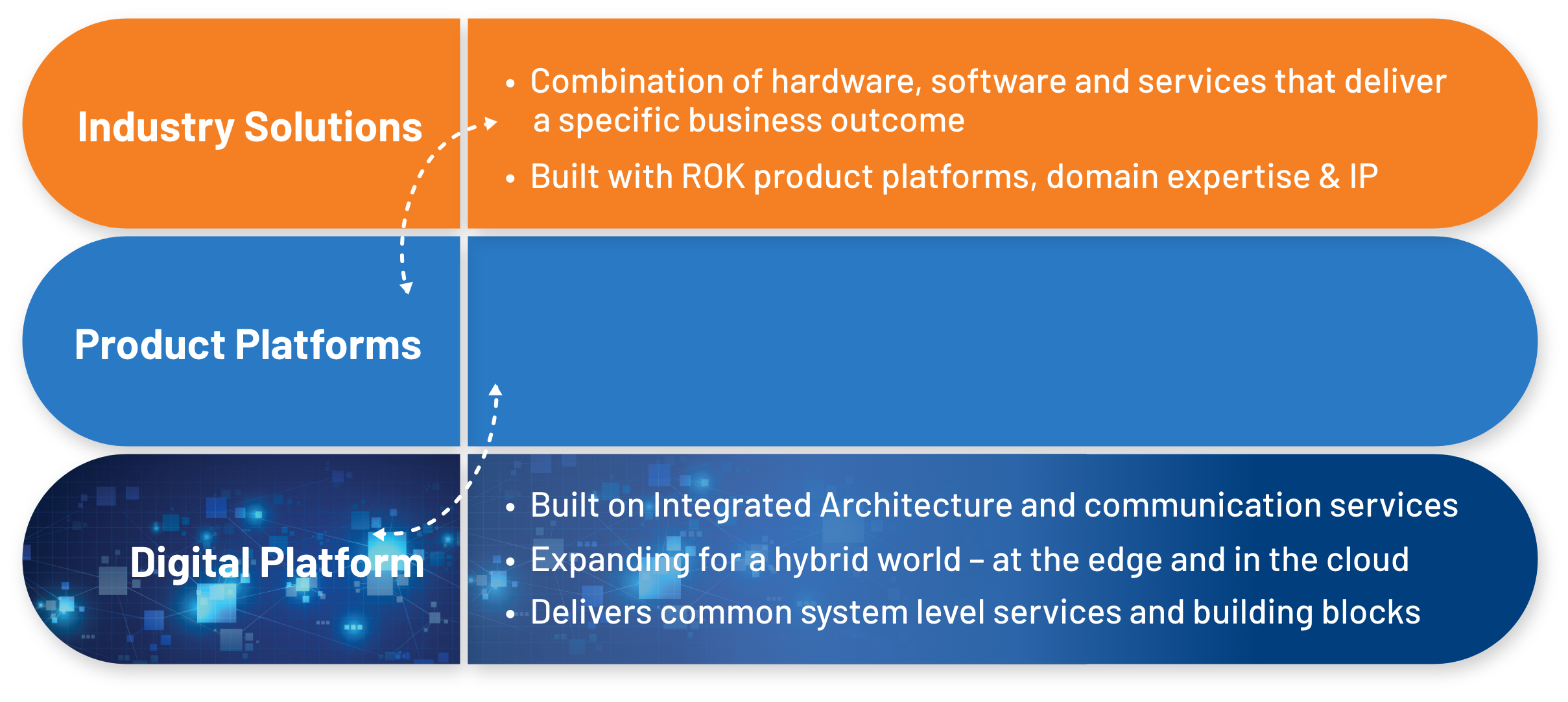

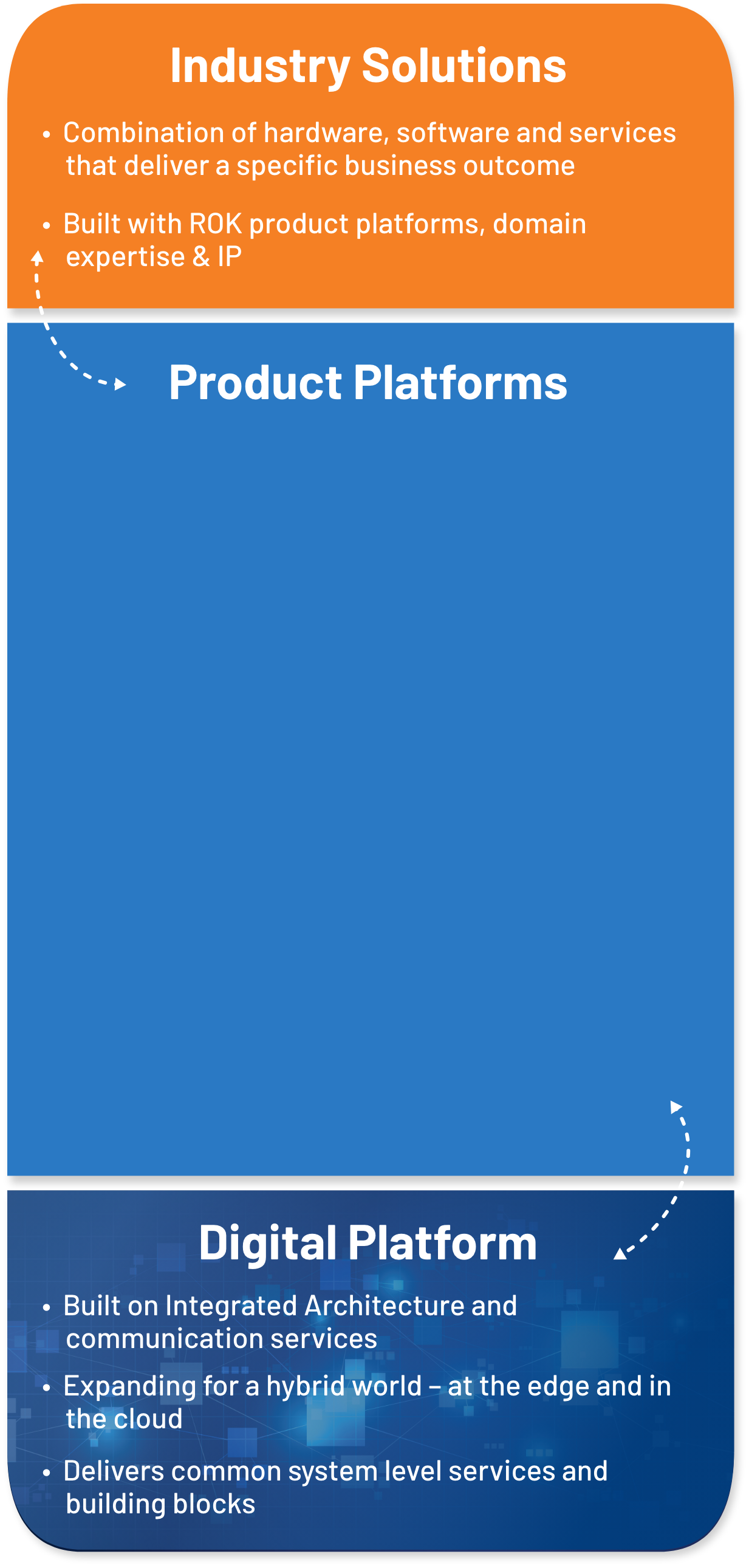

Scalable Innovation

We deliver industry-specific solutions while leveraging our best-in-class horizontal product platforms and Artificial Intelligence (AI) at every level of the technology stack to drive scale and ease of use for our customers

ROK Operating Model

Our Operating Model is a sustainable framework for operational excellence, resilient through business cycles

We've established a long-term foundation for growth by integrating best practices with new developments. This model acts as a flywheel, driving market-beating growth, expanding margins, and ensuring precise internal operations. Our high-performance culture enables us to innovate and excel in a rapidly evolving landscape.

Our commitment to operational excellence ensures we consistently deliver superior results and value to our customers.

Meeting customers where they are

Rockwell meets customers wherever they are in their journey — from automating a Greenfield plant to the digital transformation of an entire manufacturing operation

Our culture is the foundation for all we do.

Our commitment to integrity, diversity and inclusion helps fuel fresh ideas. We measure ourselves against the best alternatives, cultivating innovation, and increasing the speed of decision-making.