Improve Plant and Machine Maintenance with Equipment Remanufacturing

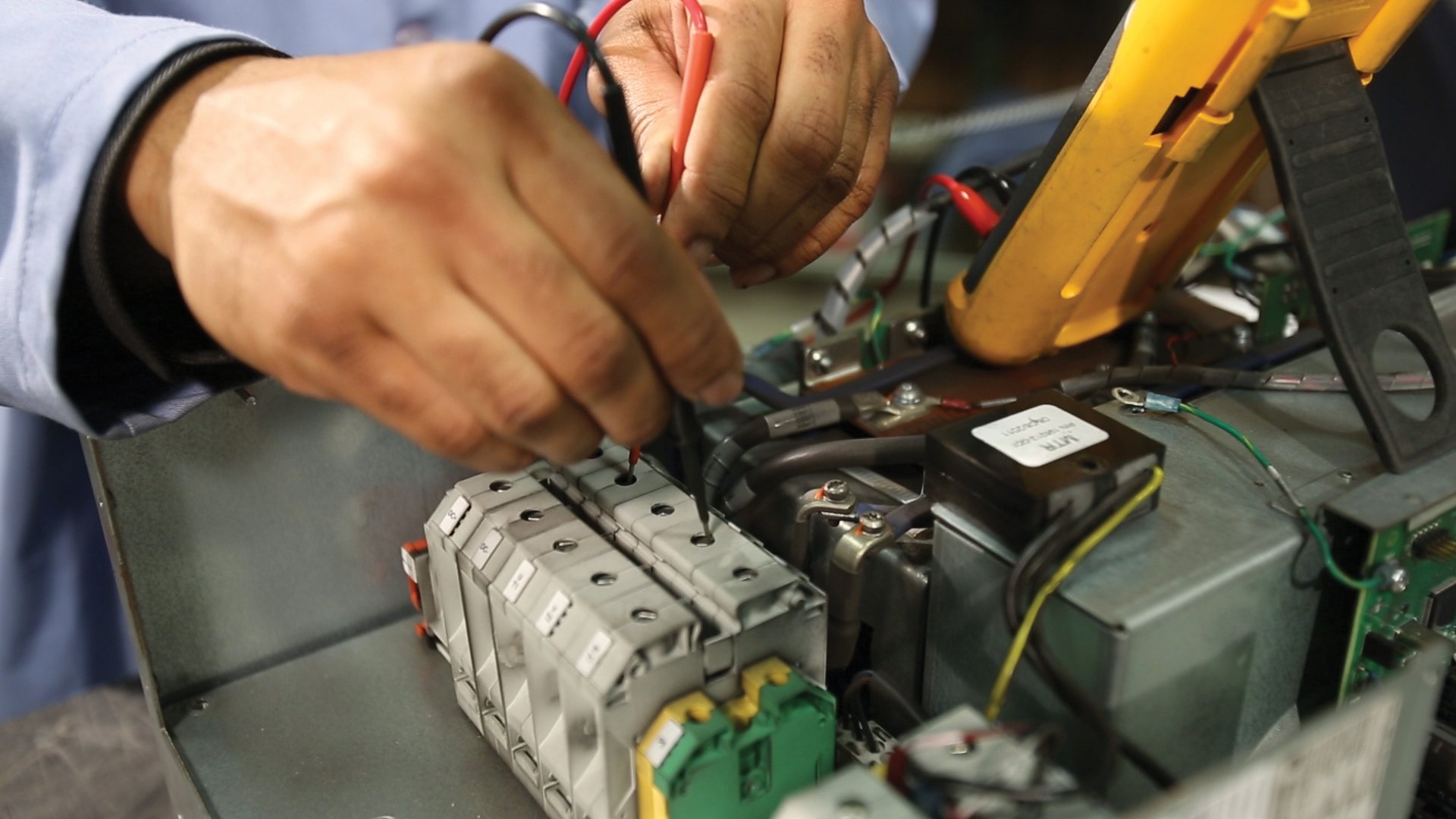

To reduce downtime and improve plant and machine maintenance, you need a reliable service partner whom you can trust to provide quality repairs when you need them. With a proven and consistent process in place, you can restore your Allen‑Bradley and Reliance Electric equipment to its original operating condition to make sure it will function reliably.